Establishment of Energy-saving Dust Collection and Ventilation System

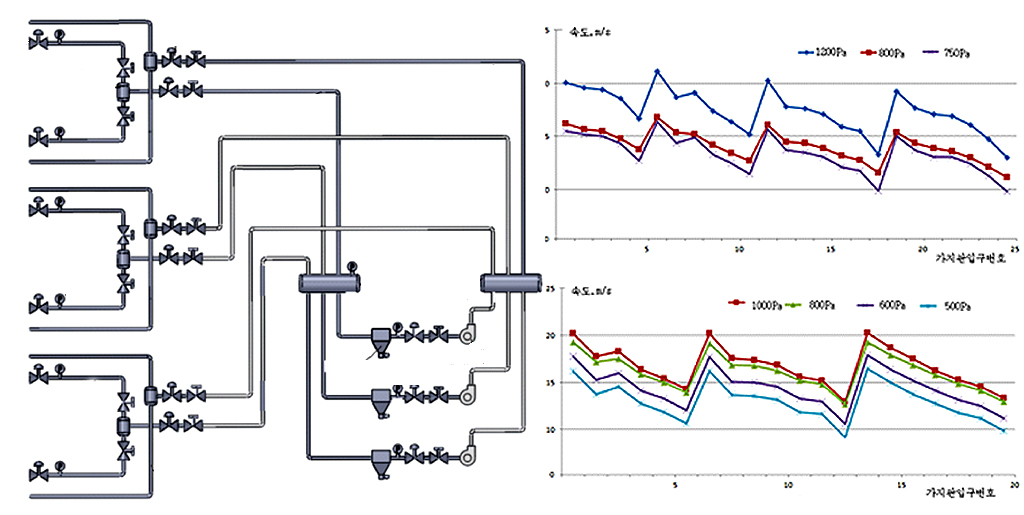

A research group led by Hong Sang Ryong, a researcher at the Faculty of Heat Engineering, has been working hard to make further achievements since he established an energy-saving recirculation system for dust collection and ventilation that can keep clean environment at the working places in a timber mill. The system makes it possible to reduce power assumption to the minimum by adjusting the number of ventilators and dust collectors to the operation rate of wood working machinery. They determined reasonable working parameters of the air control valve to prevent deposit of rough wood chips in the pneumatic conveying pipe. They also selected optimal jet time and close-down time of the pulse system in the dust collector. As a result, they reduced the number of working ventilators and dust collectors and ensured a long working life of the bag filter, which led to high working safety and low operational cost of the dust collection and ventilation system.

A research group led by Hong Sang Ryong, a researcher at the Faculty of Heat Engineering, has been working hard to make further achievements since he established an energy-saving recirculation system for dust collection and ventilation that can keep clean environment at the working places in a timber mill. The system makes it possible to reduce power assumption to the minimum by adjusting the number of ventilators and dust collectors to the operation rate of wood working machinery. They determined reasonable working parameters of the air control valve to prevent deposit of rough wood chips in the pneumatic conveying pipe. They also selected optimal jet time and close-down time of the pulse system in the dust collector. As a result, they reduced the number of working ventilators and dust collectors and ensured a long working life of the bag filter, which led to high working safety and low operational cost of the dust collection and ventilation system.

Intelligent Laser Bird Repeller with Deep Neural Network

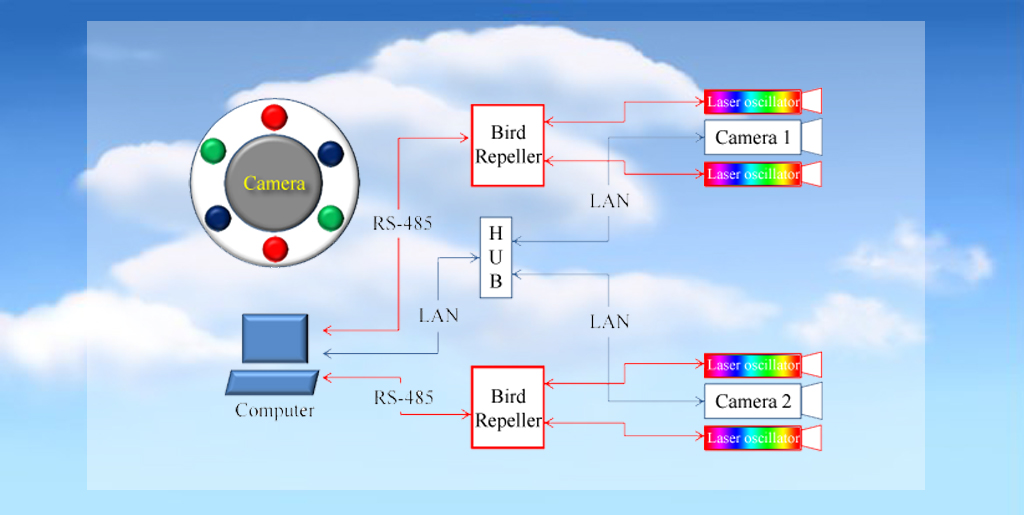

A research group led by Kim Sun Il, a researcher at the Faculty of Metal Engineering, has introduced his invention, an intelligent laser bird repeller with a deep neural network. By comparison with existing repellers, the system of this bird repeller, whose design and database are based on sufficient experimental research into birds in various kinds and sizes, is programmed to undergo constant update, thus ensuring greater efficiency in bird detection and classification. It detects birds by means of a camera, decides the mode of attack suitable for the detection results and sends signals to the laser driver device before attacking. It consists of three parts ― a laser attack unit combined with an outdoor monitoring camera, a laser driver unit and a computer processing unit. The laser attack unit consisting of the bunch of green (532nm), blue (420nm) and red (650nm) lasers of 1W is embedded in the outdoor monitoring camera. Once an image is sent to the computer, it detects and tracks the bird and sends a signal to the bird repeller device using artifical intelligence technology. This device emanates laser light driver signals according to the kind and size of birds and the intensity of light dependent on the weather change. The interface consists of monitor, statistics, log, main setting, etc. With 98.7% detection rate and 95.3% repelling rate, the fully automated system is applicable to all places including farms, fish farms, orchards and airfields that are exposed to the damage by birds.

A research group led by Kim Sun Il, a researcher at the Faculty of Metal Engineering, has introduced his invention, an intelligent laser bird repeller with a deep neural network. By comparison with existing repellers, the system of this bird repeller, whose design and database are based on sufficient experimental research into birds in various kinds and sizes, is programmed to undergo constant update, thus ensuring greater efficiency in bird detection and classification. It detects birds by means of a camera, decides the mode of attack suitable for the detection results and sends signals to the laser driver device before attacking. It consists of three parts ― a laser attack unit combined with an outdoor monitoring camera, a laser driver unit and a computer processing unit. The laser attack unit consisting of the bunch of green (532nm), blue (420nm) and red (650nm) lasers of 1W is embedded in the outdoor monitoring camera. Once an image is sent to the computer, it detects and tracks the bird and sends a signal to the bird repeller device using artifical intelligence technology. This device emanates laser light driver signals according to the kind and size of birds and the intensity of light dependent on the weather change. The interface consists of monitor, statistics, log, main setting, etc. With 98.7% detection rate and 95.3% repelling rate, the fully automated system is applicable to all places including farms, fish farms, orchards and airfields that are exposed to the damage by birds.

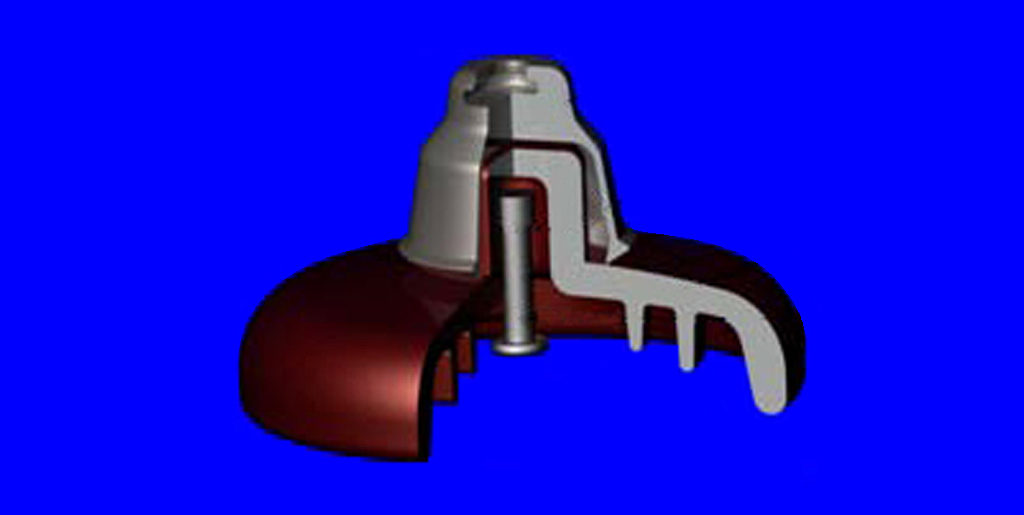

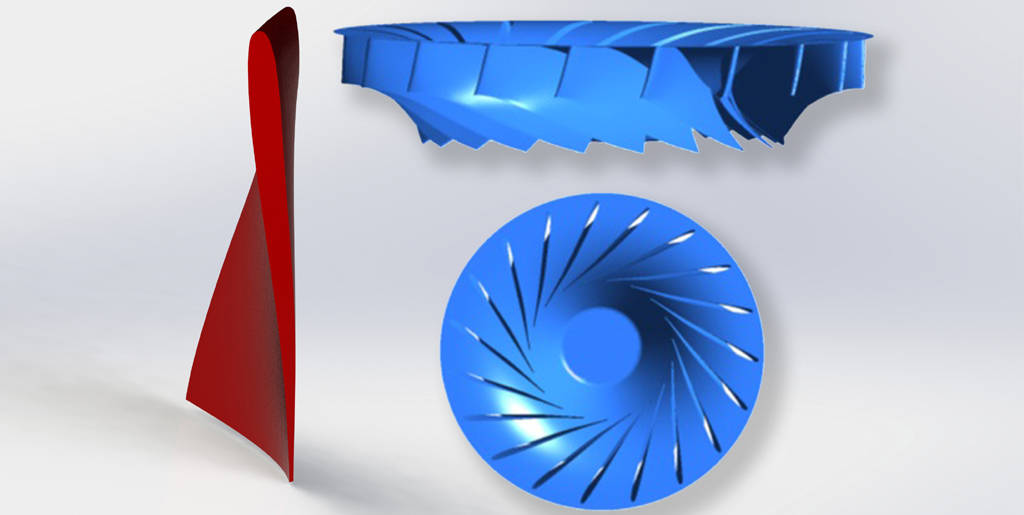

Speed Control Device of Turbo Coupling

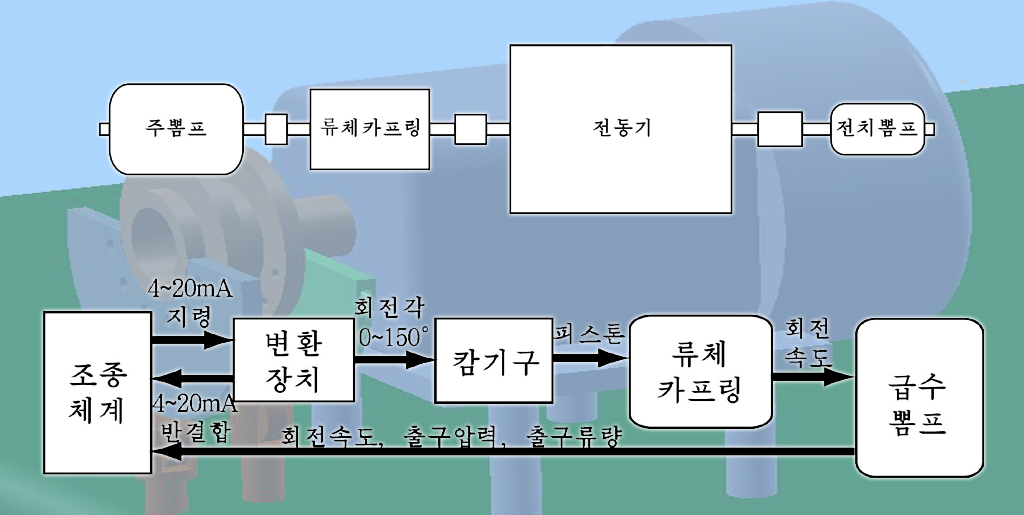

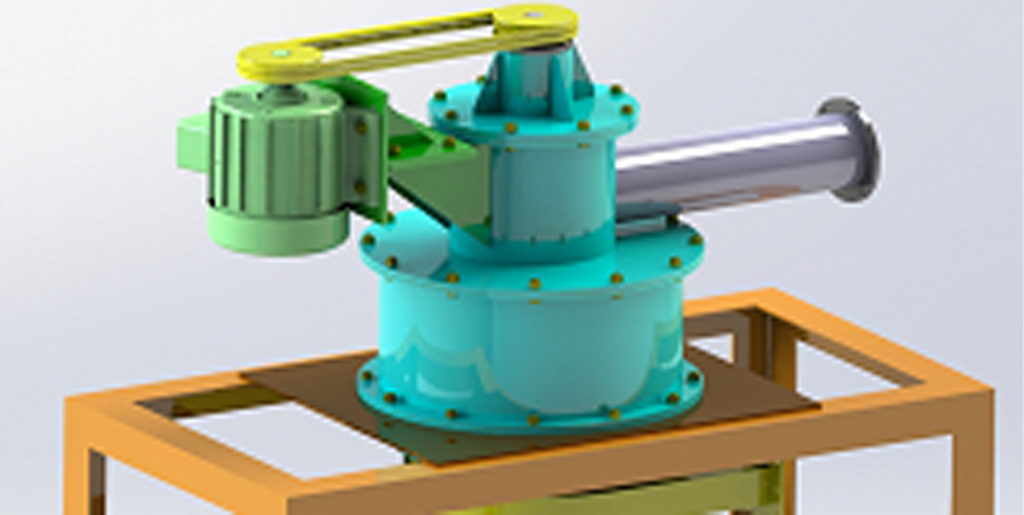

Ri Yong Ho, a section head at the Faculty of Heat Engineering, has been working hard to make further achievements since he developed a speed control device of a turbo coupling which is widely used in the speed change coupling of a large rotating machine. The device consists of a turbo coupling, a speed control instrument and a distributed control system. The fluid coupling, a power transfer device of a rotating machine, can control speed, has a wide control range and has good control characteristics. With a good power transfer characteristic, it can raise energy efficiency. To use the turbo coupling’s speed control function, we must get a correct understanding of the turbo coupling’s working principle before designing and making a speed control instrument based on it. The oil system of a turbo coupling consists of a lubricating oil system and a hydraulic oil system. The lubricating oil system functions as a supplier to provide lubricating oil to the coupling’s gears and medals while the hydraulic oil system controls rotating speed. The deeper the coupling is submerged in the oil, the larger the viscosity of oil gets and the faster the output rotating speed gets. The depth of the oil depends on the height of the dipper pipe. The flow control piston controls oil discharge which passes through the turbo coupling. The depth of the dipper pipe piston controls the rotating speed; the flow control piston controls the amount of hydraulic oil discharge to allow the turbo coupling to work. The speed control instrument consists of a rotating motor that converts the control system’s command into the rotation angle, and cam accessories. The rotating motor receives 4~20mA current signals from the control system and in proportion to it, rotates the axis in the range of 0~150°, feeds it back to the control system in proportion to the rotated angle. Two cams are installed on the axis of the conversion device, and they press on the fluid control piston and the dipper pipe piston individually according to the rotated angle. The main components of the conversion device are the two cams. Based on the piston’s working principle, the working cycle, the size and installation conditions of the speed control instrument, the cam’s curve radii are decided as follows. The fluid control cam’s radius: min = 96mm, max =115mm.

Ri Yong Ho, a section head at the Faculty of Heat Engineering, has been working hard to make further achievements since he developed a speed control device of a turbo coupling which is widely used in the speed change coupling of a large rotating machine. The device consists of a turbo coupling, a speed control instrument and a distributed control system. The fluid coupling, a power transfer device of a rotating machine, can control speed, has a wide control range and has good control characteristics. With a good power transfer characteristic, it can raise energy efficiency. To use the turbo coupling’s speed control function, we must get a correct understanding of the turbo coupling’s working principle before designing and making a speed control instrument based on it. The oil system of a turbo coupling consists of a lubricating oil system and a hydraulic oil system. The lubricating oil system functions as a supplier to provide lubricating oil to the coupling’s gears and medals while the hydraulic oil system controls rotating speed. The deeper the coupling is submerged in the oil, the larger the viscosity of oil gets and the faster the output rotating speed gets. The depth of the oil depends on the height of the dipper pipe. The flow control piston controls oil discharge which passes through the turbo coupling. The depth of the dipper pipe piston controls the rotating speed; the flow control piston controls the amount of hydraulic oil discharge to allow the turbo coupling to work. The speed control instrument consists of a rotating motor that converts the control system’s command into the rotation angle, and cam accessories. The rotating motor receives 4~20mA current signals from the control system and in proportion to it, rotates the axis in the range of 0~150°, feeds it back to the control system in proportion to the rotated angle. Two cams are installed on the axis of the conversion device, and they press on the fluid control piston and the dipper pipe piston individually according to the rotated angle. The main components of the conversion device are the two cams. Based on the piston’s working principle, the working cycle, the size and installation conditions of the speed control instrument, the cam’s curve radii are decided as follows. The fluid control cam’s radius: min = 96mm, max =115mm.

The dipper pipe cam’s radius: min = 96mm, max =117mm.

If the above-mentioned turbo coupling is installed between the main feed pump and the motor of the 210MW boiler-turbine block, it controls the rotating speed of the feed pump, which enables to control the output water pressure and the drum level of the boiler.

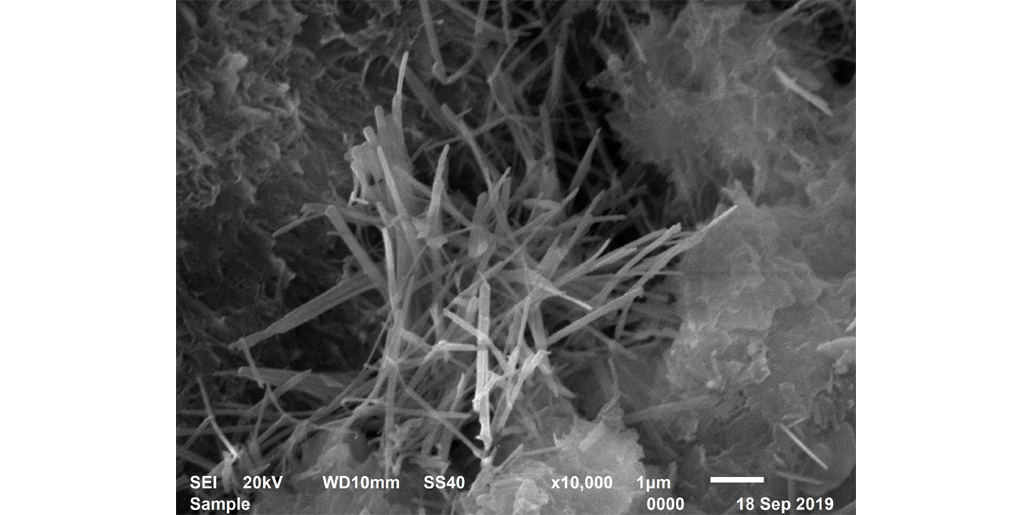

Removal of Harmful Explosion Gas using Vermiculite and Acidic Deposits of Mine Water

A research group led by Choe Yong Chol, a researcher at the Faculty of Mining Engineering, has been employing his new method of reducing the amount of harmful explosion gas by using vermiculite and acidic deposits of mine water. Introducing this technology, you can increase the power of explosion much higher than before thanks to the increase in the work ability resulted from the evaporation of combined water in vermiculite as well as the increase in brisance resulted from the increase in explosive density. At the same time, you can reduce the emission of harmful explosion gas such as CO and NOx by adsorption of expanded vermiculite, absorption of water separated from vermiculite and oxidation of metallic oxides in vermiculite at high temperature of explosion. This method has two stages; manufacturing stage where vermiculite that passed through crushing, separating and distributing processes and acidic deposits of mine water are mixed, and application stage where they are admixed with explosives. Explosive additives are made with vermiculite of 0.1mm~1.5mm in granulation size and acidic deposits of mine water less than 0.05mm in granulation size in the proportion 3:1. This mixture and Expanded Ammonium Nitrate Explosives are mixed evenly in a ratio of one to five and put into blasting cartridges before use. Most of the acidic deposits of mine water consist of ferric hydroxide(Fe(OH)3) and basic ferric sulphate(Fe(OH)SO4). In vermiculite, some metallic oxides such as ferric oxide make up about 5.5%, which is less than those contained in acidic deposits of mine water. Trihydric ferric salt and ferric oxides serve as oxidizers that oxidize CO and NO in explosion gas to CO2 and NO2 respectively. Vermiculite contains about 15% of interformational water which is not changed between micaceous layers at low temperatures but converted into water vapor at over hundreds of degrees. This interformational water removes harmful gases by absorbing soluble gases like NO2, N2O3, N2O4, etc. produced from explosive reactions and from oxidation by trihydric ferric constituents in the additives. Vermiculite has a strong cation exchange ability. Its cation exchange capacity and base absorption capacity increases by 1.5 times at high temperatures. Thus, at high explosion temperatures vermiculites are expanded and the absorption ability for harmful explosion gas is further increased. When explosives are mixed with vermiculites and acidic deposits of mine water that are heavier than constituents of explosives, the charge density of explosives increases. Consequently, the detonation velocity and pressure increase and the dynamic explosion power of explosives gets higher. Vermiculite has a maximum of 18% of interformational and combined waters, which are changed into water vapour at the moment of explosion and expanded thousands of times in volume. It results in a considerable increase in the volume of explosion gas and in the explosion pressure of explosives, which leads to the increase in the static power and blast effects. If this additive(vermiculit and acidic deposit of mine water) makes up 20% in explosives, removal rate for CO and NOx gases can be more than 93% and 85% respectively. The explosion power of explosives remains similar to or gets higher than before.

A research group led by Choe Yong Chol, a researcher at the Faculty of Mining Engineering, has been employing his new method of reducing the amount of harmful explosion gas by using vermiculite and acidic deposits of mine water. Introducing this technology, you can increase the power of explosion much higher than before thanks to the increase in the work ability resulted from the evaporation of combined water in vermiculite as well as the increase in brisance resulted from the increase in explosive density. At the same time, you can reduce the emission of harmful explosion gas such as CO and NOx by adsorption of expanded vermiculite, absorption of water separated from vermiculite and oxidation of metallic oxides in vermiculite at high temperature of explosion. This method has two stages; manufacturing stage where vermiculite that passed through crushing, separating and distributing processes and acidic deposits of mine water are mixed, and application stage where they are admixed with explosives. Explosive additives are made with vermiculite of 0.1mm~1.5mm in granulation size and acidic deposits of mine water less than 0.05mm in granulation size in the proportion 3:1. This mixture and Expanded Ammonium Nitrate Explosives are mixed evenly in a ratio of one to five and put into blasting cartridges before use. Most of the acidic deposits of mine water consist of ferric hydroxide(Fe(OH)3) and basic ferric sulphate(Fe(OH)SO4). In vermiculite, some metallic oxides such as ferric oxide make up about 5.5%, which is less than those contained in acidic deposits of mine water. Trihydric ferric salt and ferric oxides serve as oxidizers that oxidize CO and NO in explosion gas to CO2 and NO2 respectively. Vermiculite contains about 15% of interformational water which is not changed between micaceous layers at low temperatures but converted into water vapor at over hundreds of degrees. This interformational water removes harmful gases by absorbing soluble gases like NO2, N2O3, N2O4, etc. produced from explosive reactions and from oxidation by trihydric ferric constituents in the additives. Vermiculite has a strong cation exchange ability. Its cation exchange capacity and base absorption capacity increases by 1.5 times at high temperatures. Thus, at high explosion temperatures vermiculites are expanded and the absorption ability for harmful explosion gas is further increased. When explosives are mixed with vermiculites and acidic deposits of mine water that are heavier than constituents of explosives, the charge density of explosives increases. Consequently, the detonation velocity and pressure increase and the dynamic explosion power of explosives gets higher. Vermiculite has a maximum of 18% of interformational and combined waters, which are changed into water vapour at the moment of explosion and expanded thousands of times in volume. It results in a considerable increase in the volume of explosion gas and in the explosion pressure of explosives, which leads to the increase in the static power and blast effects. If this additive(vermiculit and acidic deposit of mine water) makes up 20% in explosives, removal rate for CO and NOx gases can be more than 93% and 85% respectively. The explosion power of explosives remains similar to or gets higher than before.

With the introduction of this method to all kinds of blasting operations such as driving, you can save a considerable amount of explosives and make a contribution to protecting the environment and improving working conditions by reducing the emission of harmful explosion gas.

Plasma Water Treatment Device

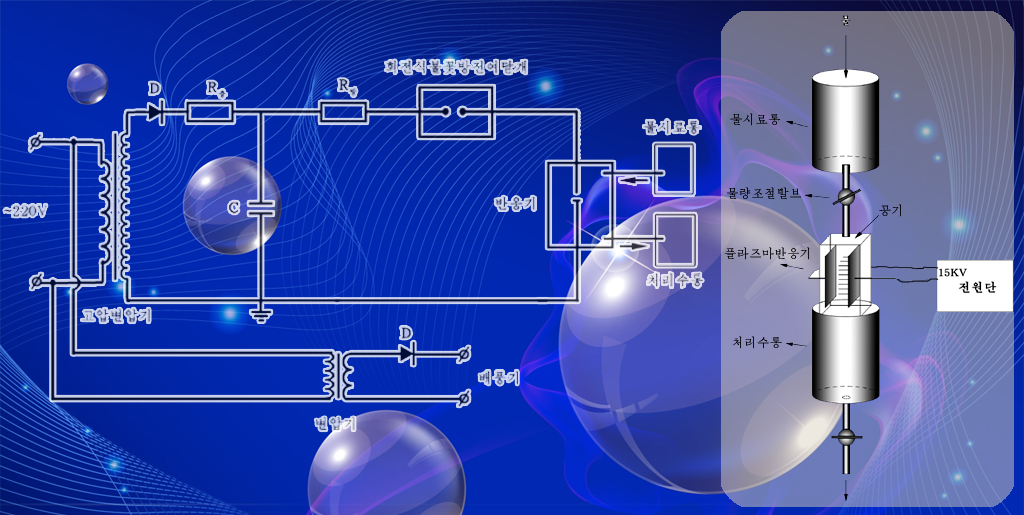

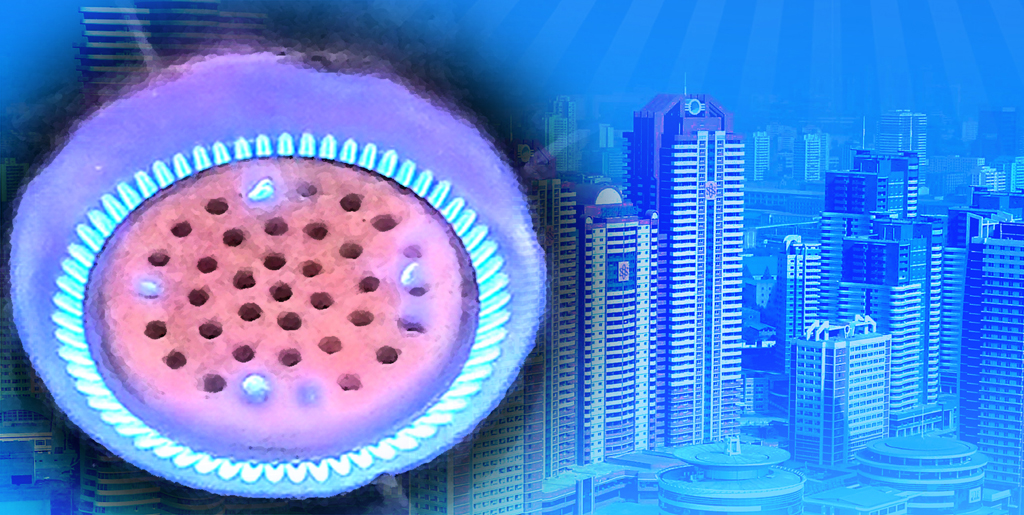

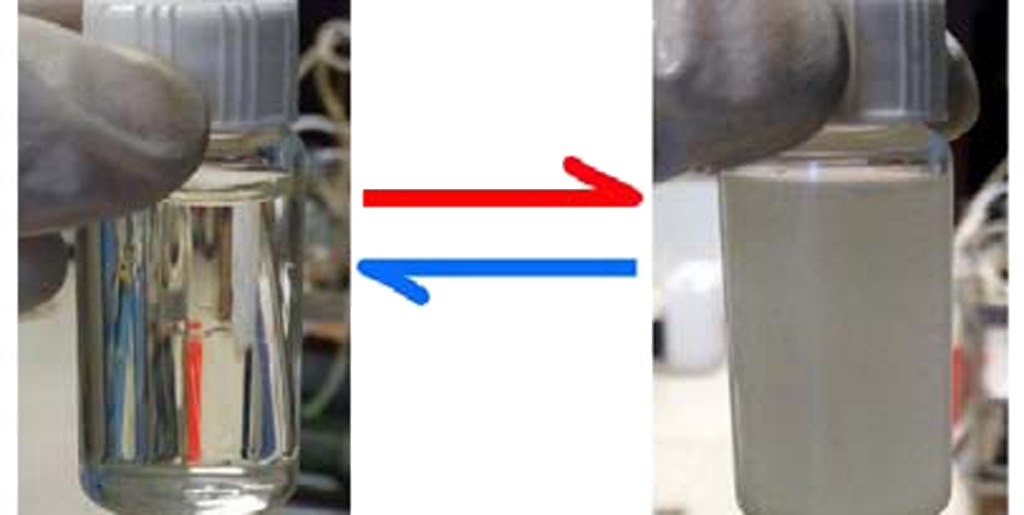

Jang Ui Jun, a researcher at the Faculty of Earth Science and Technology, has developed a plasma water treatment device, an experimental device for education and research, which enables experiments for improving the quality of groundwater and surface water to be conducted in combination with laboratory conditions and field characteristics, and verified its utility. In general, water treatment devices for improving the quality of groundwater or surface water include chlorine sterilizers, various kinds of filters such as activated carbon filters, UV disinfecters, ozone sterilizers and plasma sterilizers. A plasma water treatment device, one of advanced water treatment devices, is able to overcome the limitations of the above-mentioned water treatment devices and conduct sterilization and water treatment comprehensively and efficiently by means of active chemical species as well as ultraviolet and ozone. It consists of a power supply unit for geneartion of pulsed high voltage, a plasma reactor, a water sample tank and a water control valve and a tank for treated water. Using this plasma water treatment device, we can do experiments the aim of which is to reduce the contents of various water quality indicators contained in contaminated surface water or groundwater, especially some elements such as Fe2+, to remove bacteria including Escherichia coli, and to improve water quality.

Jang Ui Jun, a researcher at the Faculty of Earth Science and Technology, has developed a plasma water treatment device, an experimental device for education and research, which enables experiments for improving the quality of groundwater and surface water to be conducted in combination with laboratory conditions and field characteristics, and verified its utility. In general, water treatment devices for improving the quality of groundwater or surface water include chlorine sterilizers, various kinds of filters such as activated carbon filters, UV disinfecters, ozone sterilizers and plasma sterilizers. A plasma water treatment device, one of advanced water treatment devices, is able to overcome the limitations of the above-mentioned water treatment devices and conduct sterilization and water treatment comprehensively and efficiently by means of active chemical species as well as ultraviolet and ozone. It consists of a power supply unit for geneartion of pulsed high voltage, a plasma reactor, a water sample tank and a water control valve and a tank for treated water. Using this plasma water treatment device, we can do experiments the aim of which is to reduce the contents of various water quality indicators contained in contaminated surface water or groundwater, especially some elements such as Fe2+, to remove bacteria including Escherichia coli, and to improve water quality.

This device, compared to the aeration method, helps increase the rate of oxidation of Fe2+ ions in water by more than 2.5 times and raise recognition effect by providing visual effects.

Plasma Air Purifier

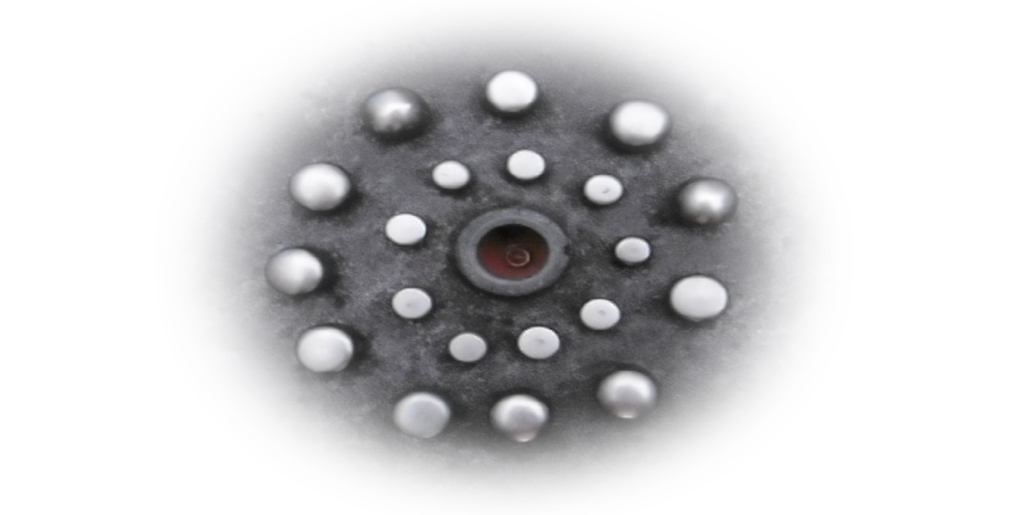

Pak Song Chol, a researcher at the Faculty of Physical Engineering, has developed an air purifier by making use of the characteristics of non-equilibrium plasma. The device employs non-thermal plasma, anti-bacterial nano material, ultra-violet ray(UV) and anion, which enables sterilization and air-purification in a pure physical mechanism without recourse to any chemical disinfectant harmful to human body. The plasma air purifier consists of pre-filter, non-equilibrium plasma generator, activated carbon filter, nano photo-catalyst grid, ultraviolet ray sterilizer, anion generator, etc. In the non-equilibrium plasma generator, high voltage of 10~15kV should be applied between the line or needle electrode and the plane electrode so that the nuclei of various microorganisms can be destroyed and burnt, and particles be ionized and absorbed. This ensures about 90% of sterilization and dust-collection efficiency for particles smaller than 0.1㎛ in size. In the nano photo-catalyst grid, UV rays, electrons, excited molecules, oxygen radicals (O2.) collide with TiO2 on the nano-TiO2 grid and activate it. Various chemical reactions take place on the activated TiO2, resulting in formation of hydroxyl radicals(OH.) and activated oxygen atoms with strong organic destruction and sterilization ability. The ultraviolet sterilizer uses a UV lamp emitting UV rays of 253.7nm in wavelength with high germicidal power. The anion generator produces a great number of air anions that are good for human health and effective in purification of atmospheric wastes, nitrogen oxides and smoke, neutralizes charged particles and eliminates room odour in an effective way. Compared with fiber-based filters (95% dust collection rate for particles larger than 0.5μm in diameter) in terms of sterilization property, the plasma air purifier can sterilize more than 95% of room air within an hour and over 98% within two hours.

Pak Song Chol, a researcher at the Faculty of Physical Engineering, has developed an air purifier by making use of the characteristics of non-equilibrium plasma. The device employs non-thermal plasma, anti-bacterial nano material, ultra-violet ray(UV) and anion, which enables sterilization and air-purification in a pure physical mechanism without recourse to any chemical disinfectant harmful to human body. The plasma air purifier consists of pre-filter, non-equilibrium plasma generator, activated carbon filter, nano photo-catalyst grid, ultraviolet ray sterilizer, anion generator, etc. In the non-equilibrium plasma generator, high voltage of 10~15kV should be applied between the line or needle electrode and the plane electrode so that the nuclei of various microorganisms can be destroyed and burnt, and particles be ionized and absorbed. This ensures about 90% of sterilization and dust-collection efficiency for particles smaller than 0.1㎛ in size. In the nano photo-catalyst grid, UV rays, electrons, excited molecules, oxygen radicals (O2.) collide with TiO2 on the nano-TiO2 grid and activate it. Various chemical reactions take place on the activated TiO2, resulting in formation of hydroxyl radicals(OH.) and activated oxygen atoms with strong organic destruction and sterilization ability. The ultraviolet sterilizer uses a UV lamp emitting UV rays of 253.7nm in wavelength with high germicidal power. The anion generator produces a great number of air anions that are good for human health and effective in purification of atmospheric wastes, nitrogen oxides and smoke, neutralizes charged particles and eliminates room odour in an effective way. Compared with fiber-based filters (95% dust collection rate for particles larger than 0.5μm in diameter) in terms of sterilization property, the plasma air purifier can sterilize more than 95% of room air within an hour and over 98% within two hours.

With the introduction of this device to production processes of foodstuff, various electronic products such as IC and medical appliances, to the interiors of buildings of medical facilities like hospitals, and to large-scale cultural and welfare facilities crowded with people, you will purify the air and guarantee hygienic safety and quality of products.

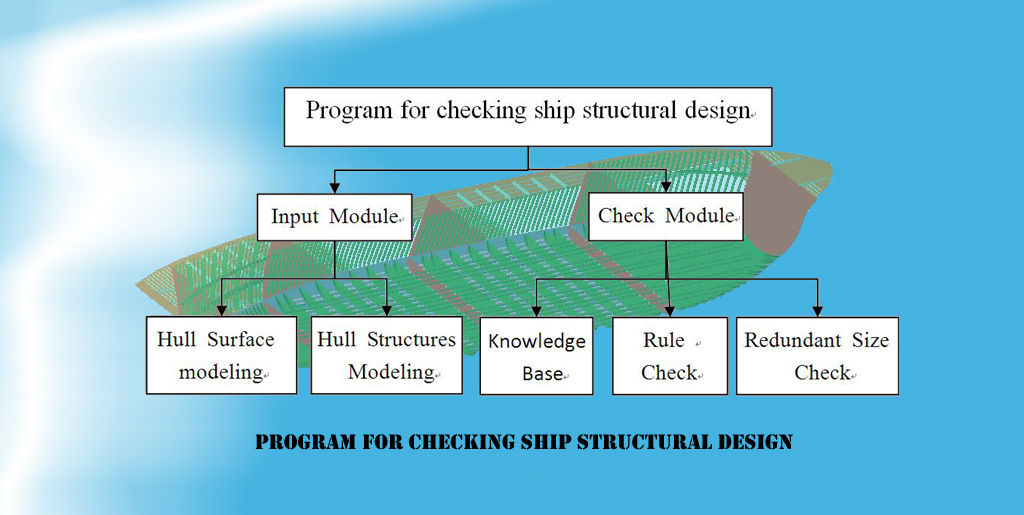

Program for Checking Structural Design of Ships

The research team led by Pae Ho Rim, a section head at the Faculty of Shipbuilding and Ocean Engineering, has developed a program for checking structural designs of ships. This program will put checking of structural designs of ships on an IT basis, thus improving checking accuracy and reducing time and effort for checking. This program consists of input module and check module for structural design. In the input module, structural design data for checking are input with substructures of a ship hull as a unit. Design data for substructures include information about the locations and dimensions of plates and stiffeners, components of the substructure. Check module is composed of 3 parts; knowledge base, rule check and redundant size check. In addition, it has an automatic making function of structural design check report. Rules and examples of design check are saved in the knowledge base. At present, checking of structural design of ships is being conducted manually by many experts in naval architecture, involving a great deal of time and effort. In contrast, this program needs only one expert to finish design checking with 100% accuracy within 2 days.

The research team led by Pae Ho Rim, a section head at the Faculty of Shipbuilding and Ocean Engineering, has developed a program for checking structural designs of ships. This program will put checking of structural designs of ships on an IT basis, thus improving checking accuracy and reducing time and effort for checking. This program consists of input module and check module for structural design. In the input module, structural design data for checking are input with substructures of a ship hull as a unit. Design data for substructures include information about the locations and dimensions of plates and stiffeners, components of the substructure. Check module is composed of 3 parts; knowledge base, rule check and redundant size check. In addition, it has an automatic making function of structural design check report. Rules and examples of design check are saved in the knowledge base. At present, checking of structural design of ships is being conducted manually by many experts in naval architecture, involving a great deal of time and effort. In contrast, this program needs only one expert to finish design checking with 100% accuracy within 2 days.

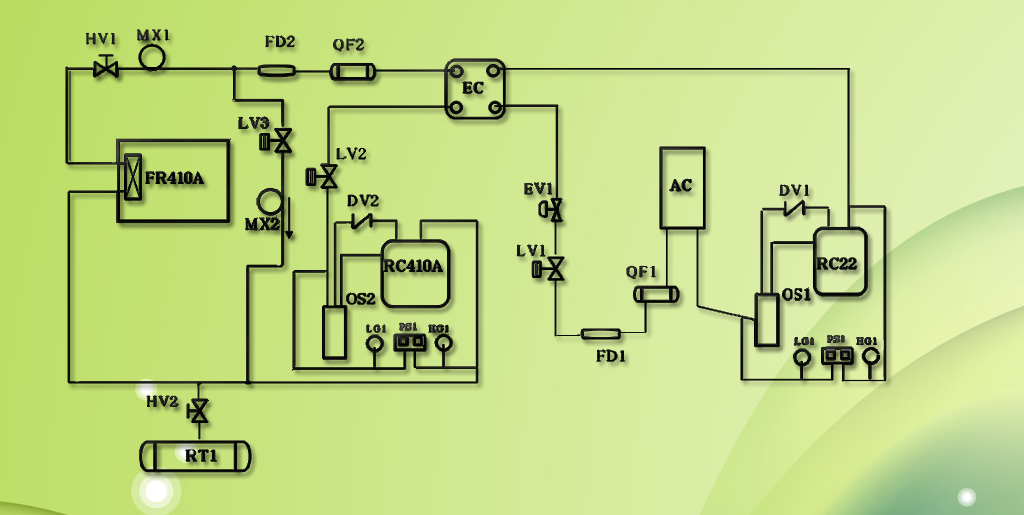

Cascade Cryogenic Refrigerator Designed and Manufactured

The research group led by Ri Ju Hyok, a section head at the Faculty of Heat Engineering, has succeeded in designing and manufacturing a cascade cryogenic refrigerator for new material development and cryogenic environmental experiment. Operated by the cascade refrigeration cycle, it is composed of two refrigeration cycles ― hot cycle and cold cycle. In the hot cycle, middle refrigerants are used, and in the cold cycle, low refrigerants are used. Each cycle is an individual refrigeration system using one refrigerant each. Evaporation of the refrigerant in the hot cycle is used for condensation of the refrigerant in the cold cycle. The two cycles are connected by an evaporator-condenser that functions as a condenser for the cold cycle and as an evaporator for the hot cycle. The heat gained from the cold cycle is transferred to the refrigerant in the hot cycle that transfers the heat to the environment. The hot cycle is composed of a hot cycle compressor, an air cooling condenser, a throttle valve and an evaporator-condenser, etc. while the cold cycle is made up of a cold cycle compressor, a capillary tube, an evaporator, an expansion vessel, an evaporator-condenser, etc. An evaporator-condenser can be designed and manufactured as a high efficiency plate or a dual tube heat exchanger. This cascade cryogenic refrigerator, which provides a temperature range of -40℃~-160℃, has wide applicability to several fields including machine, chemical and electronic industries, biological and metallic material engineering, public health, national defence and sports.

The research group led by Ri Ju Hyok, a section head at the Faculty of Heat Engineering, has succeeded in designing and manufacturing a cascade cryogenic refrigerator for new material development and cryogenic environmental experiment. Operated by the cascade refrigeration cycle, it is composed of two refrigeration cycles ― hot cycle and cold cycle. In the hot cycle, middle refrigerants are used, and in the cold cycle, low refrigerants are used. Each cycle is an individual refrigeration system using one refrigerant each. Evaporation of the refrigerant in the hot cycle is used for condensation of the refrigerant in the cold cycle. The two cycles are connected by an evaporator-condenser that functions as a condenser for the cold cycle and as an evaporator for the hot cycle. The heat gained from the cold cycle is transferred to the refrigerant in the hot cycle that transfers the heat to the environment. The hot cycle is composed of a hot cycle compressor, an air cooling condenser, a throttle valve and an evaporator-condenser, etc. while the cold cycle is made up of a cold cycle compressor, a capillary tube, an evaporator, an expansion vessel, an evaporator-condenser, etc. An evaporator-condenser can be designed and manufactured as a high efficiency plate or a dual tube heat exchanger. This cascade cryogenic refrigerator, which provides a temperature range of -40℃~-160℃, has wide applicability to several fields including machine, chemical and electronic industries, biological and metallic material engineering, public health, national defence and sports.

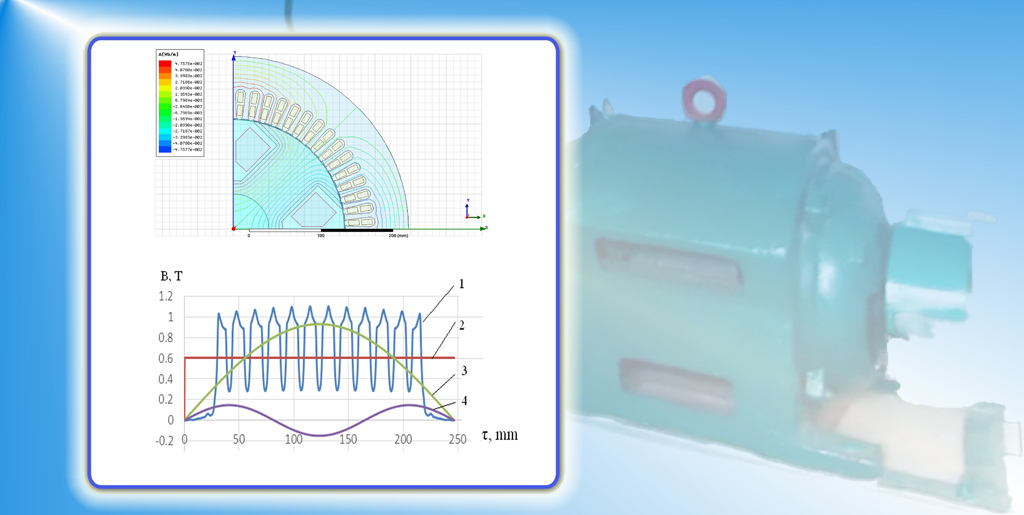

Method of Voltage Stabilization of 3 Harmonics Exciting Synchronous Generator

Cha Myong Song, a researcher at the Faculty of Electrical Engineering, has completed the principle and method for stabilizing voltage from no-load state to normal load state.

Cha Myong Song, a researcher at the Faculty of Electrical Engineering, has completed the principle and method for stabilizing voltage from no-load state to normal load state.

Although existing 3 harmonics exciting synchronous generators realized the stabilization of voltage by changing the structure of pole shoes, they failed to provide a reasonable value range of 3 harmonics flux density. According to the new method, 3 harmonics flux density and the output power of 3 harmonics winding and exciting winding are decided and the windings are connected to exciting regulation resistors in order to improve the efficiency of the generator and decrease voltage changing rate. The 3 harmonics exciting synchronous generator, which consists of 1 harmonics winding, 3 harmonics winding, full-wave recification circuit, exciting winding, exciting regulation resistor, guarantees enough self exciting and decreases voltage changing rate by regulating the parameters of 3 harmonics winding, exciting winding, pole structure and exciting regulation resistors. If 3 harmonics flux density is much higher than 1 harmonics flux density, voltage waveform gets non-sinusoidal, and if much lower, self exciting may not occur. Therefore, 3 harmonics flux density should be defined within the range of 4~6% of 1 harmonics flux density by the field analysis method. The parameters of 3 harmonics winding and exciting winding should be defined to be reasonable by the equivalent circuit method. The efficiency of the generator and the exciting stability depend on the designs of 3 harmonics winding and exciting winding. The 3 harmonics exciting synchronous generator is low in manufacturing cost and ensures enough self exciting in it. Its voltage changing rate decreases to 1.4% and its efficiency improves to 90.9%. This method of voltage stabilization is also applicable to small independent gas generators.

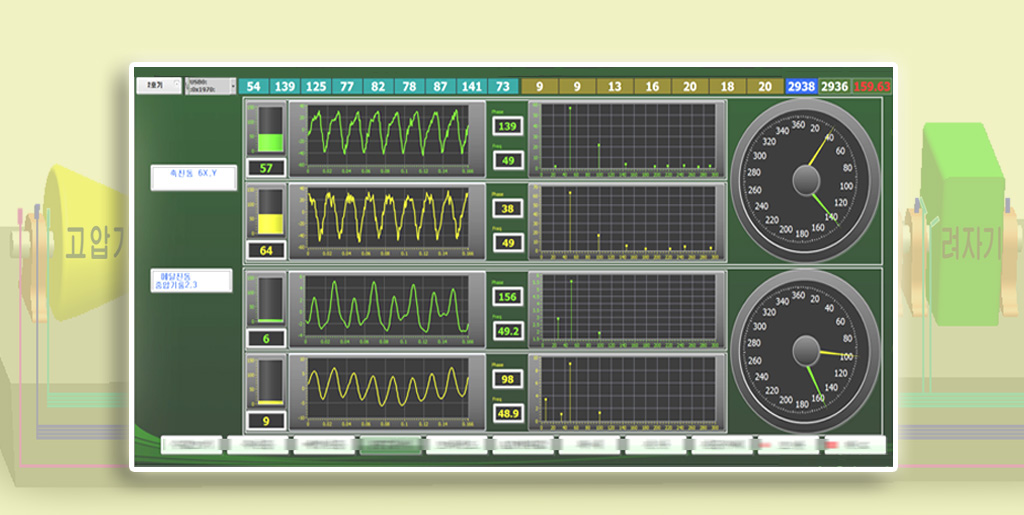

Multi-channel Vibration Instrument

Ri Yong Ho, a section head at the Faculty of Heat Engineering, has developed an instrument that can measure and analyze vibration of rotating machinery such as steam turbine generators real-time.

Ri Yong Ho, a section head at the Faculty of Heat Engineering, has developed an instrument that can measure and analyze vibration of rotating machinery such as steam turbine generators real-time.

As a steam turbine generator is composed of rotors that are supported by their pedestals, vibration state of all the pedestals should be measured and analyzed at the same time by a multi-channel instrument. The multi-channel vibration instrument acquires vibration signals of up to 16 channels at high speed at the same time and transmits them to the computer so that one can measure and analyze vibration state of all the pedestals of turbine generators, diagnose vibration fault and decrease vibration level by taking necessary measures like balancing. The multi-channel vibration instrument is composed of analog signal processing circuit, key-phase pulse input circuit, digital signal processing circuit, USB communication circuit and power supply circuit. The analog signal processing circuit does overvoltage protection, filtering and amplification of vibration signals, and then sends them to the digital signal processing circuit. Digital signal processing is performed by a microchip, in which AD conversion of 16-channel analog signals, measurement of the rotating speed and vibration phase by key-phase pulse, saving of vibration waveforms and communication control take place. The acquired vibration waveforms of 16 channels are transmitted immediately to the microchip which has USB communication function by means of parallel communication mode and then they are real-time transmitted to computers through USB ports. In the power supply circuit, AC 220V power is converted to stable direct current voltages 5V and ±12Vand then supplied to every signal processing circuit. The computer performs digital filtering and integral of multi-channel vibration waveforms received from the vibration instrument, transforms vibration acceleration signals into vibration velocity signals and vibration displacement signals, calculates vibration amplitude to measure vibration level, and then makes vibration analyses such as spectrum analysis by fast Fourier transformation, phase analysis and trend analysis. Besides, it can perform one-plane balancing and two-plane balancing by method of influence coefficient, so field balancing of steam turbine generators can be realized. We can measure pedestal vibration by linking this instrument with piezoelectric acceleration sensors and electromagnetic speed sensors, and shaft vibration is also measurable when it is connected with eddy displacement sensors. The measurement range is 0~200㎛ in the case of pedestal vibration and 0~500㎛ in the case of shaft vibration, and the measurement accuracy is 2%.

Experiment Device for Vibration Measurement of Ship Hull Model

The research group led by Pae Ho Rim, a section head at the Faculty of Shipbuilding and Ocean Engineering, has developed an experiment device for measuring natural frequency of a ship hull.

The research group led by Pae Ho Rim, a section head at the Faculty of Shipbuilding and Ocean Engineering, has developed an experiment device for measuring natural frequency of a ship hull.

The device measures the natural frequency of a ship hull model by the principle that resonance occurs when natural frequency is coincident with the frequency of forced vibration caused by decentration mass. The device consists of ship hull model, vibration generator, unit for motor velocity control, frequency sensor, acceleration sensor, amplification and integration circuit, communication interface, user interface, etc. The model is 1.2 metres long, 0.1 metres wide and 0.1 metres high. The cross section is rectangular and the bow and stern assume a pyramidal form. The user interface shows the graphs and values of real-time signals of revolution, displacement, acceleration and velocity.

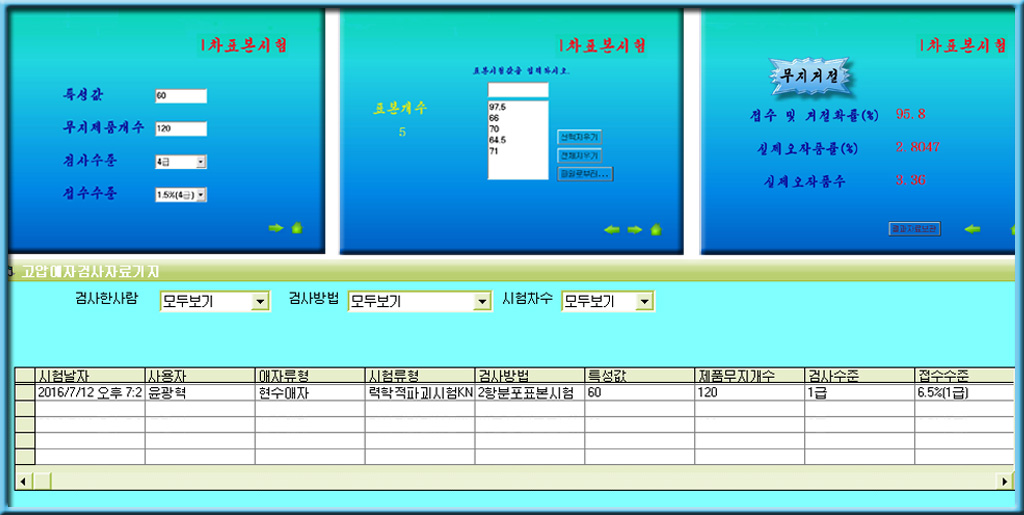

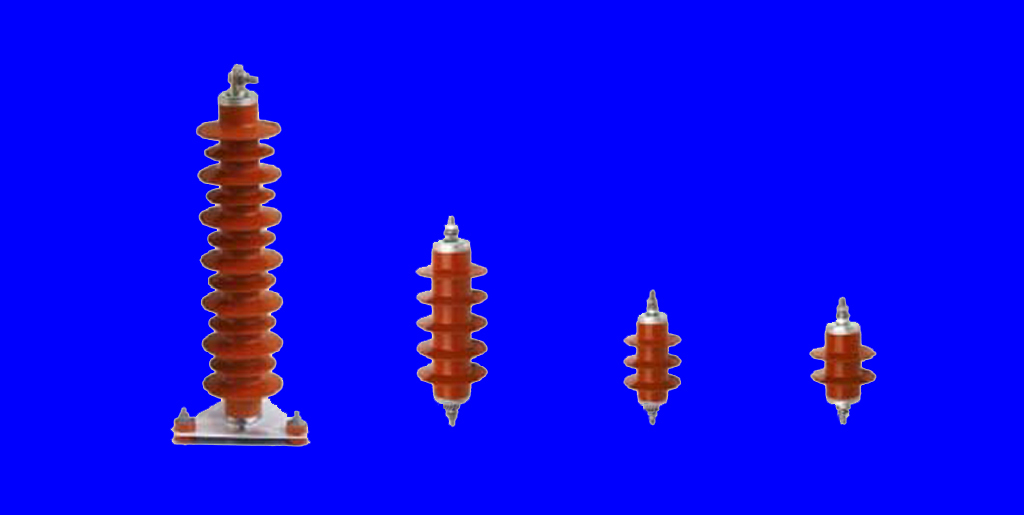

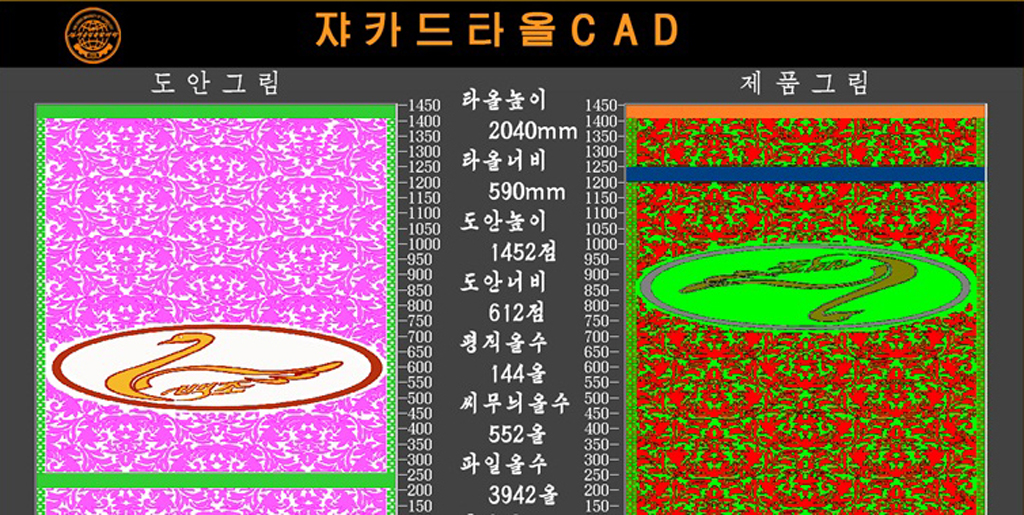

Test Method for Crack Selection in 10kV Pin Insulators

Kim Ryul, a researcher at the Faculty of Electrical Engineering, has realized selection of crack insulators from a pile of 10kV pin insulators by data processing of thermal shock sample breaking test and a corona short-circuit nondestructive test device. Compared with previous selection methods by electric penetration breakdown test, this method provides more safety and lower production cost. In addition, as it uses nondestructive electric tests to sort out crack insulators, the reliability of production pile of insulators can be further improved. This method is constructed with several stages: determination of size of 10kV pin insulator piles and samples, thermal shock sample destructive test, state decision of pass or pass failure of production piles by processing test data, determination of acceptance probability by quality control software and of the number of faulty insulators, and selection of crack pin insulators by the corona short-circuit nondestructive selection device. This thermal shock test costs less and provides 1.4 times higher accuracy than the previous electric penetration breakdown test. To estimate cracks in 10kV pin insulator piles, previous binomial distribution was replaced with noncentral t-distribution, which reduced the number of samples to half and improved the accuracy of acceptance probability of piles and the calculation of the number of crack insulators by 1.2 times. Instead of electric penetration breakdown test devices, corona nondestructive test devices were used, which made it possible to select 100% of crack insulators from passed piles.

Kim Ryul, a researcher at the Faculty of Electrical Engineering, has realized selection of crack insulators from a pile of 10kV pin insulators by data processing of thermal shock sample breaking test and a corona short-circuit nondestructive test device. Compared with previous selection methods by electric penetration breakdown test, this method provides more safety and lower production cost. In addition, as it uses nondestructive electric tests to sort out crack insulators, the reliability of production pile of insulators can be further improved. This method is constructed with several stages: determination of size of 10kV pin insulator piles and samples, thermal shock sample destructive test, state decision of pass or pass failure of production piles by processing test data, determination of acceptance probability by quality control software and of the number of faulty insulators, and selection of crack pin insulators by the corona short-circuit nondestructive selection device. This thermal shock test costs less and provides 1.4 times higher accuracy than the previous electric penetration breakdown test. To estimate cracks in 10kV pin insulator piles, previous binomial distribution was replaced with noncentral t-distribution, which reduced the number of samples to half and improved the accuracy of acceptance probability of piles and the calculation of the number of crack insulators by 1.2 times. Instead of electric penetration breakdown test devices, corona nondestructive test devices were used, which made it possible to select 100% of crack insulators from passed piles.

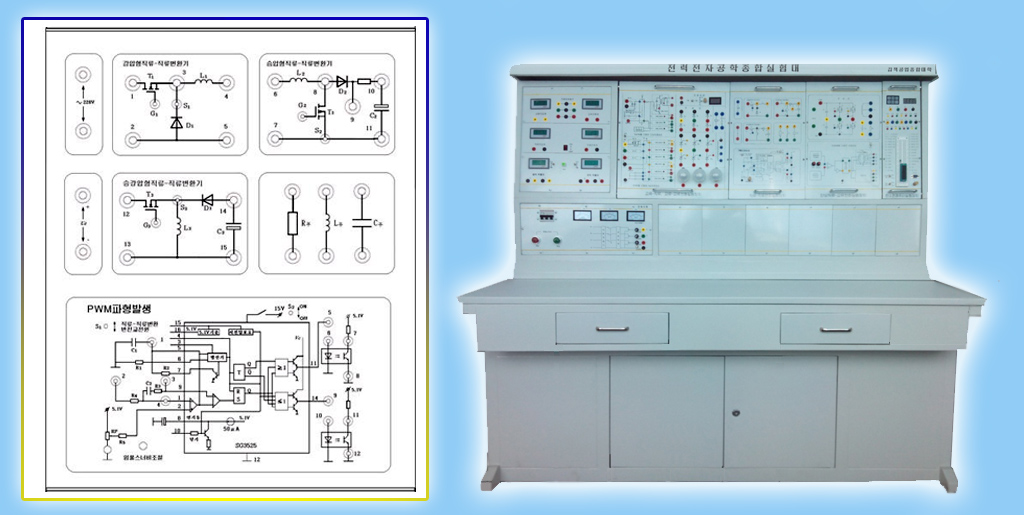

DC-DC Chopper Experimental Equipment

Ho Tong Chol, a researcher at the Faculty of Electrical Engineering, has developed DC-DC chopper experimental equipment, a part of a power electronics integrated laboratory table. It is designed to enable experiments on typical DC-DC converters ― Buck, Boost and Buck-Boost. It can easily get an operational waveform at any point thanks to the terminals placed on the front-plate, it is supported by AC 220V as main power source, and the circuit diagrams of the front-plate are intuitive and plain enough to provide users with convenient environment for experiments on a certain converter. This equipment, composed of power supply, control block, driving circuit, main circuit, load and filter, is useful for raising or dropping static DC 12V and for measuring some parameters such as duty cycle, voltage and current ripple rate, instantaneous value, mean value, etc. The control block using current typed PWM integrated circuit SG3525 compares the carrier in 32.5kHz with DC voltage(0~3.3V) before it generates a PWM pulse at that comparison position. This process is observed at the terminals. Additionally, since it includes a soft-starting circuit, you can increase the duty cycle smoothly so that no shock current flows into the main switch even when it starts on the maximum duty cycle. The control range of duty cycle is 0.2 to 0.8. The control block is also available for the control of a transformer isolated DC-DC converter since it has two ground separated power supplies, which is useful for the experiment on a half-bridge DC-DC converter. The driving circuit guarantees a reliable and safe switch of the main device. The driving circuit is fed from unipolar power source. The main circuit consists of a main switching device, a reactor, FRD, a capacitor and a current sensing resistor. The load is a resistor in 200Ω and it can also include a filter when necessary. The newly-developed experimental equipment is useful to students, researchers and teachers who major in power electronics.

Ho Tong Chol, a researcher at the Faculty of Electrical Engineering, has developed DC-DC chopper experimental equipment, a part of a power electronics integrated laboratory table. It is designed to enable experiments on typical DC-DC converters ― Buck, Boost and Buck-Boost. It can easily get an operational waveform at any point thanks to the terminals placed on the front-plate, it is supported by AC 220V as main power source, and the circuit diagrams of the front-plate are intuitive and plain enough to provide users with convenient environment for experiments on a certain converter. This equipment, composed of power supply, control block, driving circuit, main circuit, load and filter, is useful for raising or dropping static DC 12V and for measuring some parameters such as duty cycle, voltage and current ripple rate, instantaneous value, mean value, etc. The control block using current typed PWM integrated circuit SG3525 compares the carrier in 32.5kHz with DC voltage(0~3.3V) before it generates a PWM pulse at that comparison position. This process is observed at the terminals. Additionally, since it includes a soft-starting circuit, you can increase the duty cycle smoothly so that no shock current flows into the main switch even when it starts on the maximum duty cycle. The control range of duty cycle is 0.2 to 0.8. The control block is also available for the control of a transformer isolated DC-DC converter since it has two ground separated power supplies, which is useful for the experiment on a half-bridge DC-DC converter. The driving circuit guarantees a reliable and safe switch of the main device. The driving circuit is fed from unipolar power source. The main circuit consists of a main switching device, a reactor, FRD, a capacitor and a current sensing resistor. The load is a resistor in 200Ω and it can also include a filter when necessary. The newly-developed experimental equipment is useful to students, researchers and teachers who major in power electronics.

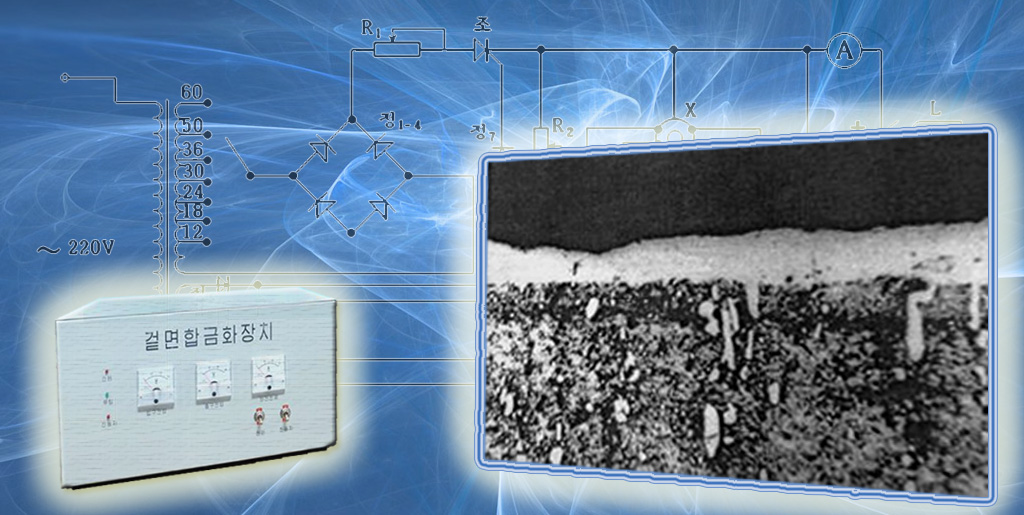

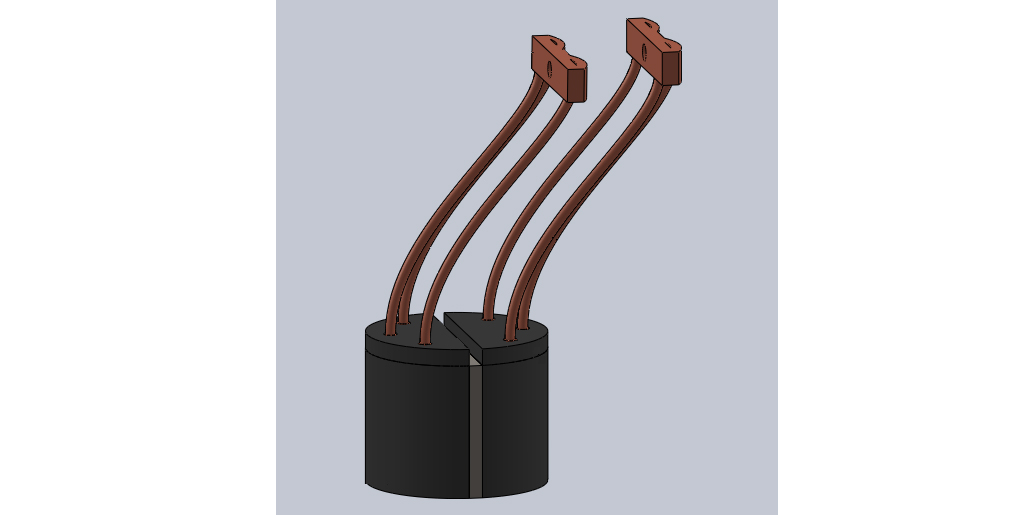

Electrode Material for Electric Spark-alloying Developed

Sim Jae Rim, a section head at the Faculty of Materials Science and Technology, has established a way of making WC-Co-B4C system electrode material for electric spark alloying and an alloying process by this material so that the service life of tools and machine parts could get more than 2.5 times as long. B4C in the material has a good effect on the formation of alloying layers since it plays the role as flux which decreases the amount of oxide scale made during electric spark alloying. It also decreases the amount of oxides of low hardness and helps the formation of carbides of high hardness. The reasonable electric conditions for electric spark alloying by WC-Co-B4C system electrode material are short circuit current I=9A, U=24V, C=420㎌ and t=2min/cm2. The thickness and hardness of an electric spark alloying layer by the new material are higher, that is, 90㎛ and 23.5GPa respectively, compared to 70㎛ and 19.5GPa by previous WC-Co system electrode material. Electric spark alloying by WC-Co-B4C system electrode material forms alloying layers of high hardness on the surfaces of tools and machine parts, which leads to the lengthening of their working life.

Sim Jae Rim, a section head at the Faculty of Materials Science and Technology, has established a way of making WC-Co-B4C system electrode material for electric spark alloying and an alloying process by this material so that the service life of tools and machine parts could get more than 2.5 times as long. B4C in the material has a good effect on the formation of alloying layers since it plays the role as flux which decreases the amount of oxide scale made during electric spark alloying. It also decreases the amount of oxides of low hardness and helps the formation of carbides of high hardness. The reasonable electric conditions for electric spark alloying by WC-Co-B4C system electrode material are short circuit current I=9A, U=24V, C=420㎌ and t=2min/cm2. The thickness and hardness of an electric spark alloying layer by the new material are higher, that is, 90㎛ and 23.5GPa respectively, compared to 70㎛ and 19.5GPa by previous WC-Co system electrode material. Electric spark alloying by WC-Co-B4C system electrode material forms alloying layers of high hardness on the surfaces of tools and machine parts, which leads to the lengthening of their working life.

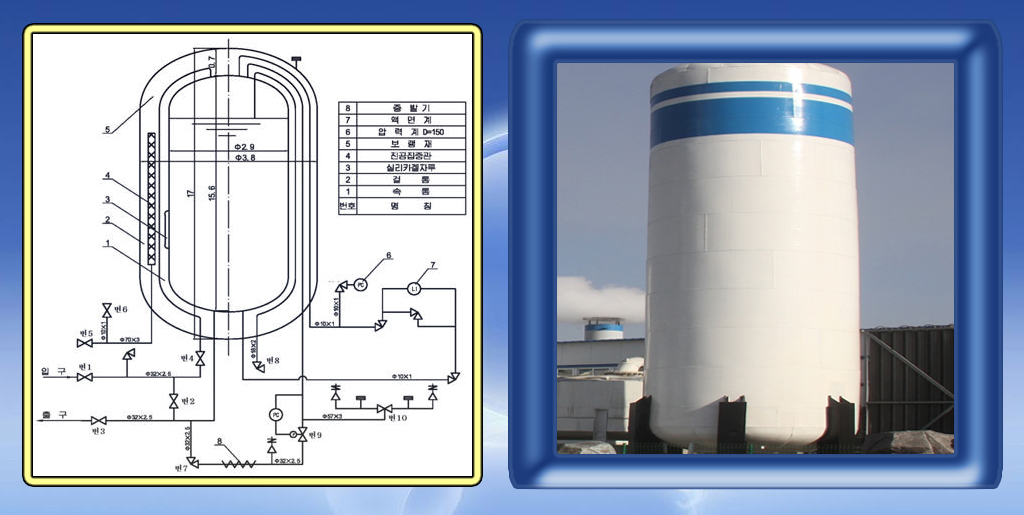

Cryogenic Liquid Tank for Storage of Oxygen Liquid Built

The research team led by Ri Ju Hyok, a section head at the Faculty of Heat Engineering, has designed and built a cryogenic liquid tank for storage of oxygen liquid. The tank is manufactured to store oxygen liquid produced by cryogenic distillation process for a certain period and to supply it in either liquid or gas form. It is composed of an inner body for storage of oxygen liquid, an outer body, a pipeline for injection and exhaustion, safety factors including checker valves, safety valves, pressure control valves, a level meter and manometers and a self-evaporator for increasing the pressure inside the tank. The space between the inner and outer bodies is filled with thermal insulation material expanded perlite and made vacuous to reduce evaporation loss and to keep cool. The problem of preserving the cold to minimize cold loss by a heat bridge was solved, which decreased daily loss to only 0.3~0.8%. The degree of vacuum in the insulated space is 1.3Pa, and the total heat conductivity of the expanded perlite is 0.017W/(m•K). With all these advantages it can also be used for storage of other cryogenic liquids like nitrogen, argon, etc. as well as oxygen.

The research team led by Ri Ju Hyok, a section head at the Faculty of Heat Engineering, has designed and built a cryogenic liquid tank for storage of oxygen liquid. The tank is manufactured to store oxygen liquid produced by cryogenic distillation process for a certain period and to supply it in either liquid or gas form. It is composed of an inner body for storage of oxygen liquid, an outer body, a pipeline for injection and exhaustion, safety factors including checker valves, safety valves, pressure control valves, a level meter and manometers and a self-evaporator for increasing the pressure inside the tank. The space between the inner and outer bodies is filled with thermal insulation material expanded perlite and made vacuous to reduce evaporation loss and to keep cool. The problem of preserving the cold to minimize cold loss by a heat bridge was solved, which decreased daily loss to only 0.3~0.8%. The degree of vacuum in the insulated space is 1.3Pa, and the total heat conductivity of the expanded perlite is 0.017W/(m•K). With all these advantages it can also be used for storage of other cryogenic liquids like nitrogen, argon, etc. as well as oxygen.

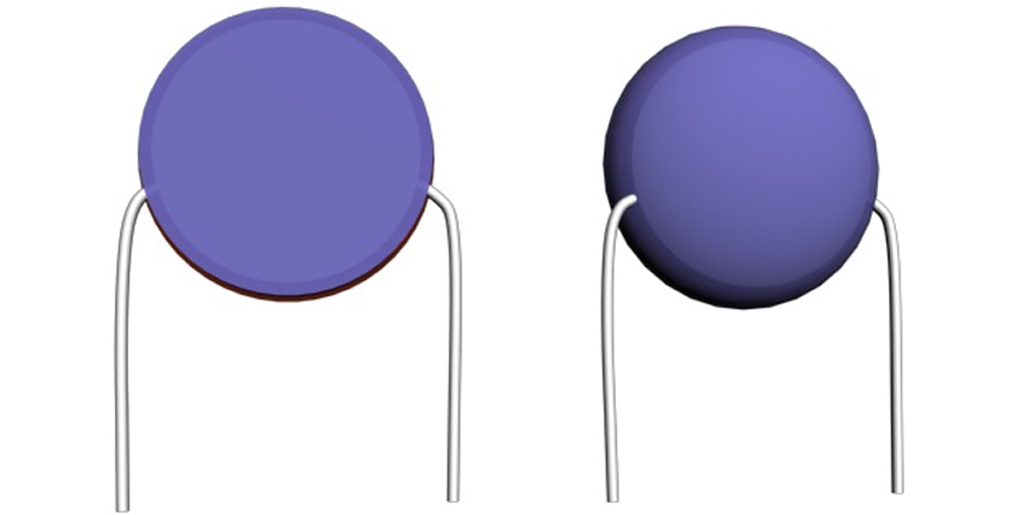

Indoor Base Station Antenna for Mobile Communication

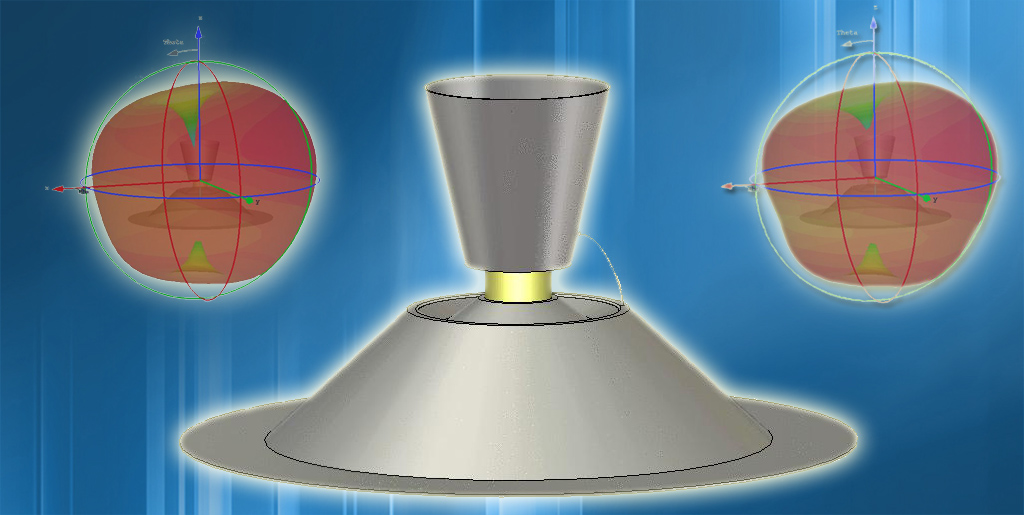

Kim Myong Il, a vice dean at the Faculty of Communications, has invented an indoor antenna for mobile communication. Compared with previous antennas, this antenna has several advantages ― it ensures enough matching, gain and horizontal omni pattern in a wide band of frequencies; it is easy to feed, produce and assemble; it is light, good-looking and easy to install. Consisting of a cone monopole, a double cone reflection panel, a curved plastic protection lid and coaxial feeding structure, the antenna assumes horizontal omni pattern in a wide range of frequency such as GSM, WCDMA, LTE, etc. With the gain of 3dBi, it can provide indoor mobile communication service in areas such as the underground of a building where mobile communication service cannot reach. As a wide-range radiator, a cone monopole has top and bottom panels made of metal (Oblique angle is 25.5, radii are 12mm and 21mm respectively.), with an impedance of 50Ω and a wide radiation area. So it is of nearly omni directional pattern on the horizontal plane. Vertical radiation can be controlled by a double cone reflection panel consisting of a primary cone reflection panel, a plain reflection panel, an upper cone reflection panel for coaxial feeding and it can bring a gain of 3dBi. The inner conductor of a feeding coaxial cable is connected to the bottom panel and the outer conductor is linked to the reflection panel. The impedance of the antenna can be controlled by inserting an inclined line between the cone monopole and the reflection panel. Therefore, the impedance of the antenna remains constant in a wide frequency range. What is more, it is easy to install on the wall and it is covered tightly with a radome made of glass fiber plastic in order to prolong the life span and give a good-looking appearance. In a wider frequency range(756~1 063/1 670~2 777MHz) than in the frequency range of former wire monopoles, the gain is 3.2dBi, which is 1.1dBi higher than former antennas (2.1dBi), so the service bound gets 1.4 times wider than before. The antenna is light, easy to install and meets aesthetic requirements.

Kim Myong Il, a vice dean at the Faculty of Communications, has invented an indoor antenna for mobile communication. Compared with previous antennas, this antenna has several advantages ― it ensures enough matching, gain and horizontal omni pattern in a wide band of frequencies; it is easy to feed, produce and assemble; it is light, good-looking and easy to install. Consisting of a cone monopole, a double cone reflection panel, a curved plastic protection lid and coaxial feeding structure, the antenna assumes horizontal omni pattern in a wide range of frequency such as GSM, WCDMA, LTE, etc. With the gain of 3dBi, it can provide indoor mobile communication service in areas such as the underground of a building where mobile communication service cannot reach. As a wide-range radiator, a cone monopole has top and bottom panels made of metal (Oblique angle is 25.5, radii are 12mm and 21mm respectively.), with an impedance of 50Ω and a wide radiation area. So it is of nearly omni directional pattern on the horizontal plane. Vertical radiation can be controlled by a double cone reflection panel consisting of a primary cone reflection panel, a plain reflection panel, an upper cone reflection panel for coaxial feeding and it can bring a gain of 3dBi. The inner conductor of a feeding coaxial cable is connected to the bottom panel and the outer conductor is linked to the reflection panel. The impedance of the antenna can be controlled by inserting an inclined line between the cone monopole and the reflection panel. Therefore, the impedance of the antenna remains constant in a wide frequency range. What is more, it is easy to install on the wall and it is covered tightly with a radome made of glass fiber plastic in order to prolong the life span and give a good-looking appearance. In a wider frequency range(756~1 063/1 670~2 777MHz) than in the frequency range of former wire monopoles, the gain is 3.2dBi, which is 1.1dBi higher than former antennas (2.1dBi), so the service bound gets 1.4 times wider than before. The antenna is light, easy to install and meets aesthetic requirements.

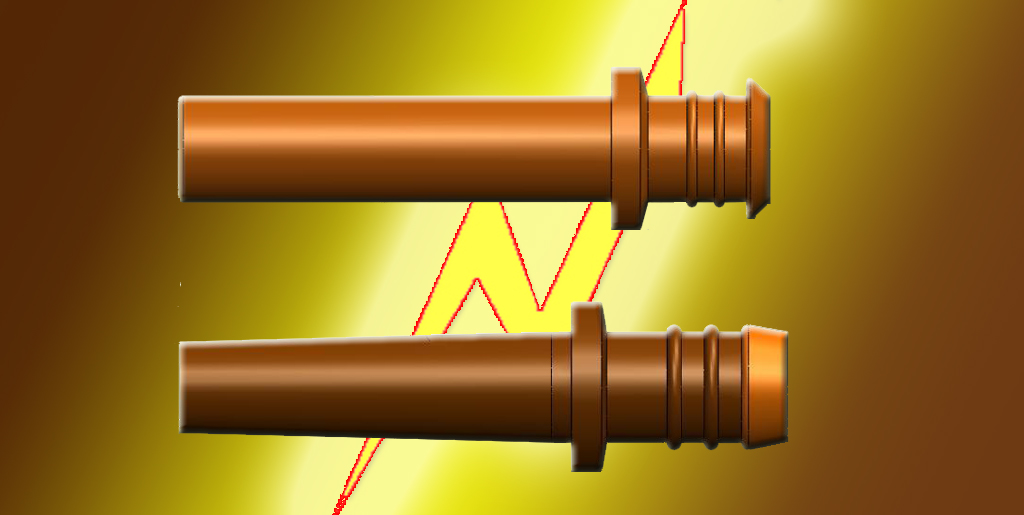

Insulation Bushing for 10kV Electric Boiler

Kim Ryul, a researcher at the Faculty of Electronics, has developed a new insulation bushing for a 10kV electric boiler that conforms to the operating conditions of the boiler and guarantees high reliability. Unlike prior bushings of a cylindrical shape for a 3-phase 3kV electric boiler, a newly-developed one is of a conical shape, satisfies the operating conditions for a 10kV electric boiler and is more reliable and lighter. As its head has been changed into a ring type, they can increase yield, which means it can help reduce the level of environmental pollution and save raw and other materials. The new bushing is lighter by 0.7 times each, which means it has now become cheaper to make. What is more, it is 2.4 times higher in dielectric strength, 3.3 times in working voltage, 1.25 times in output power, 2.7 times in 5-minute upkeep water pressure and 0.65 times lower in maximum current, which offers a scientific guarantee of the operating conditions and reliability of a 10kV electric boiler. The yield has increased up to 93%.

Kim Ryul, a researcher at the Faculty of Electronics, has developed a new insulation bushing for a 10kV electric boiler that conforms to the operating conditions of the boiler and guarantees high reliability. Unlike prior bushings of a cylindrical shape for a 3-phase 3kV electric boiler, a newly-developed one is of a conical shape, satisfies the operating conditions for a 10kV electric boiler and is more reliable and lighter. As its head has been changed into a ring type, they can increase yield, which means it can help reduce the level of environmental pollution and save raw and other materials. The new bushing is lighter by 0.7 times each, which means it has now become cheaper to make. What is more, it is 2.4 times higher in dielectric strength, 3.3 times in working voltage, 1.25 times in output power, 2.7 times in 5-minute upkeep water pressure and 0.65 times lower in maximum current, which offers a scientific guarantee of the operating conditions and reliability of a 10kV electric boiler. The yield has increased up to 93%.

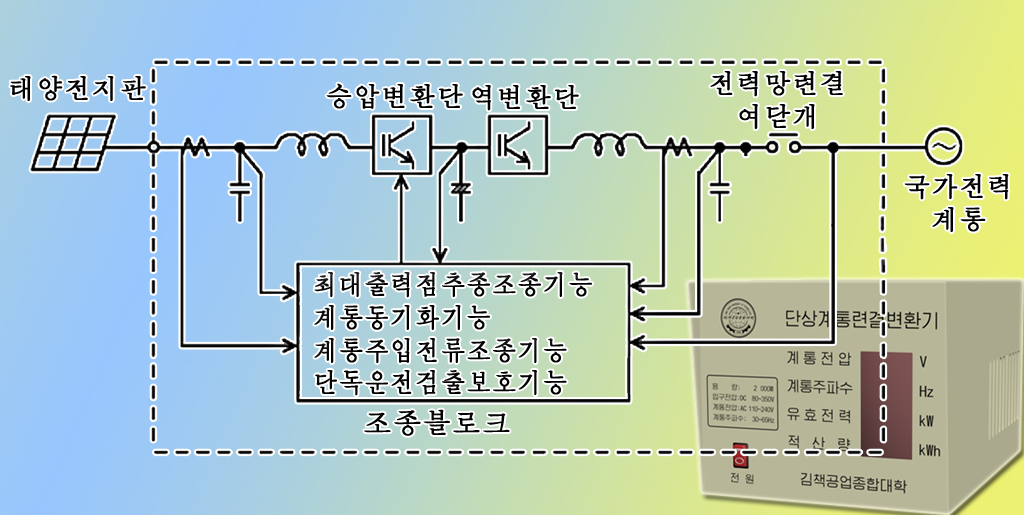

Development and Introduction of Single-Phase Grid-Connected Voltage Sourced Inverter with Reactive Power Control

A research team led by Hong Yong Jun, a researcher at the Institute of Electric Engineering, has developed and introduced a single-phase grid connected VSI(Voltage Sourced Inverter). It can not only transfer active power to the national power grid by converting the DC power generated by PV(Photovoltaic) modules into AC active power and synchronizing it with the voltage and frequency of the grid, but also control reactive power independently. They realized the control of reactive power in the grid-connected VSI by applying the IRP (instantaneous reactive power) theory, the base of the FACTS(flexible AC transmission system). For this control, they had to ensure the exact tracking of the frequency of the grid voltage by introducing the fictitious phase by the SOGI(second-order generalized integrator) and FLL(frequency locked loop). Then, they took control of grid injected current by a PR(proportional resonant) regulator with proper parameters, and added anti-islanding detection by active frequency drift. The THD(total harmonic distortion) of grid-injected current is 3.6% and the time required for anti-islanding detection is less than 0.1s.

A research team led by Hong Yong Jun, a researcher at the Institute of Electric Engineering, has developed and introduced a single-phase grid connected VSI(Voltage Sourced Inverter). It can not only transfer active power to the national power grid by converting the DC power generated by PV(Photovoltaic) modules into AC active power and synchronizing it with the voltage and frequency of the grid, but also control reactive power independently. They realized the control of reactive power in the grid-connected VSI by applying the IRP (instantaneous reactive power) theory, the base of the FACTS(flexible AC transmission system). For this control, they had to ensure the exact tracking of the frequency of the grid voltage by introducing the fictitious phase by the SOGI(second-order generalized integrator) and FLL(frequency locked loop). Then, they took control of grid injected current by a PR(proportional resonant) regulator with proper parameters, and added anti-islanding detection by active frequency drift. The THD(total harmonic distortion) of grid-injected current is 3.6% and the time required for anti-islanding detection is less than 0.1s.

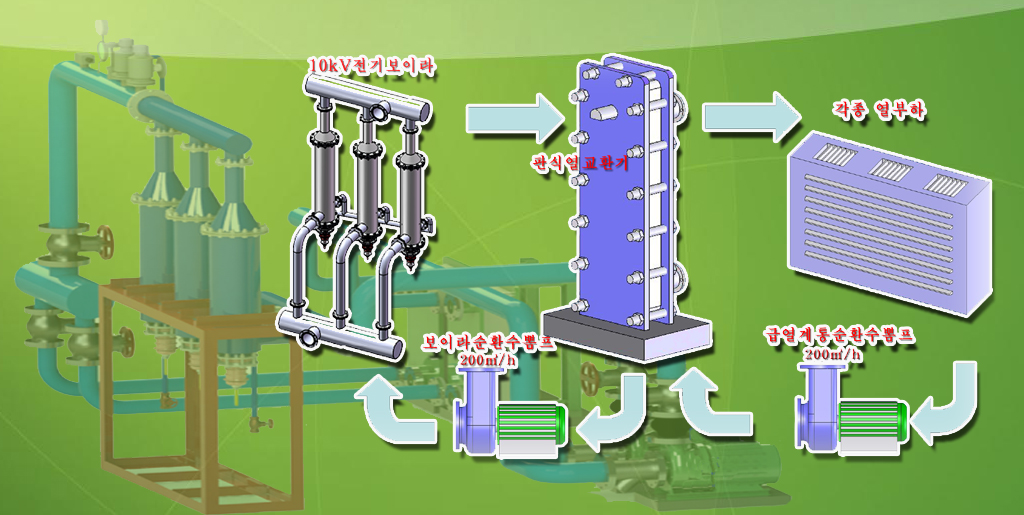

10kV Electric Boiler Developed

A research group led by Jang Ki Ho, a section head at the Faculty of Heat Engineering, has developed a 10kV electric boiler designed to use the electricity from a power system directly, and they are now working hard to make further achievements in their research. Boilers are largely divided into two types, i.e. a low voltage electric boiler (LVEB) and a high voltage electric boiler (HVEB). In a LVEB, heat is generated by Joule heating effect in an electrical resistor as an electrical heating element below 380V and is transferred to fluids. Usually, the electrical heating element used in a LVEB produces several kilowatts of thermal power. However, hundreds or thousands of kilowatts are needed to heat various kinds of liquid for swimming pools, ponds used for aquaculture, sensitive products used in chemical and agro alimentary processes and buildings. The heat power output of boilers used for controlling the load in a wind power station or a nuclear power station is the same. Even if several heating elements below 380V can be used as one, it remains uneconomic, because it needs a transformer that maintains the supply system voltage at 380V, and it also causes a considerable energy loss. On the contrary, an HVEB(10kV) offers several advantages: it produces thousands of kilowatts of high electro-thermal power, it needs comparatively low investment, it is easy to make, and it can be operated without a transformer from the direct supply from an electric power system.

A research group led by Jang Ki Ho, a section head at the Faculty of Heat Engineering, has developed a 10kV electric boiler designed to use the electricity from a power system directly, and they are now working hard to make further achievements in their research. Boilers are largely divided into two types, i.e. a low voltage electric boiler (LVEB) and a high voltage electric boiler (HVEB). In a LVEB, heat is generated by Joule heating effect in an electrical resistor as an electrical heating element below 380V and is transferred to fluids. Usually, the electrical heating element used in a LVEB produces several kilowatts of thermal power. However, hundreds or thousands of kilowatts are needed to heat various kinds of liquid for swimming pools, ponds used for aquaculture, sensitive products used in chemical and agro alimentary processes and buildings. The heat power output of boilers used for controlling the load in a wind power station or a nuclear power station is the same. Even if several heating elements below 380V can be used as one, it remains uneconomic, because it needs a transformer that maintains the supply system voltage at 380V, and it also causes a considerable energy loss. On the contrary, an HVEB(10kV) offers several advantages: it produces thousands of kilowatts of high electro-thermal power, it needs comparatively low investment, it is easy to make, and it can be operated without a transformer from the direct supply from an electric power system.

The problem is the safety of a high-voltage electric boiler. It is difficult to predict the amount of thermal power in the step of its design because it depends on the temperature, velocity and specific resistance of the fluid that are also changed in relation to each other. To solve these problems, they proposed a 10kV electric boiler equipped with a ceramic insulation tube inside and determined its geometrical sizes and operation parameters through a numerical analysis of coupled thermal, hydro mechanical and electrical fields in the water heating process. On the basis of this, they completed it through tests and practices. The investment of an 10㎸ electric boiler is under ½, and the installation area under ¼, compared to a LVEB of the same capacity. And there is no consumed power due to the operation of a transformer.

Cryogenic Liquid Oxygen Vaporizer Invented

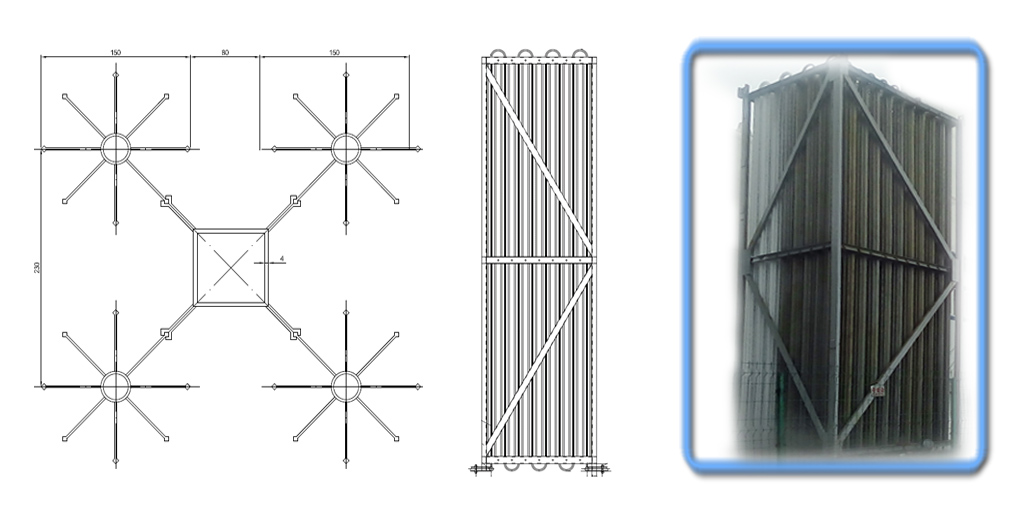

A research group led by Ri Ju Hyok, a section head at the Faculty of Heat Engineering, has invented a vaporizer that vaporizes cryogenic liquid oxygen to supply to consumers. It is an atmospheric source cryogenic vaporizer that turns cryogenic liquid oxygen into gas by cryogenic distillation method. In practice, the demand for oxygen is unpredictable. To meet this flexible demand, liquid oxygen is usually stored in the cryogenic tank and is vaporized whenever needed. The vaporization of liquid oxygen is conducted by means of a cryogenic vaporizer. The vaporizer is a vertical heat exchanger, its cross section is of an 8-pointed star type and it vaporizes cryogenic liquid by atmospheric heat. To determine the optimal parameters of a vaporizer, they studied 4 items: growth process of frost on the surface of the heat exchanger when liquid oxygen is vaporized, the property of frost, the pulse phenomenon in the heat transfer pipe and the destruction of frost on the surface, and the characteristics of air flow in the surrounding of a heat exchanger.

A research group led by Ri Ju Hyok, a section head at the Faculty of Heat Engineering, has invented a vaporizer that vaporizes cryogenic liquid oxygen to supply to consumers. It is an atmospheric source cryogenic vaporizer that turns cryogenic liquid oxygen into gas by cryogenic distillation method. In practice, the demand for oxygen is unpredictable. To meet this flexible demand, liquid oxygen is usually stored in the cryogenic tank and is vaporized whenever needed. The vaporization of liquid oxygen is conducted by means of a cryogenic vaporizer. The vaporizer is a vertical heat exchanger, its cross section is of an 8-pointed star type and it vaporizes cryogenic liquid by atmospheric heat. To determine the optimal parameters of a vaporizer, they studied 4 items: growth process of frost on the surface of the heat exchanger when liquid oxygen is vaporized, the property of frost, the pulse phenomenon in the heat transfer pipe and the destruction of frost on the surface, and the characteristics of air flow in the surrounding of a heat exchanger.

The cryogenic oxygen liquid vaporizer is extruded of aluminum alloy of good conductivity. As its heat source is based on only the air in the atmosphere, environmental problems such as pollutant emission and noises are not arisen. It is also applicable to the vaporization of other cryogenic liquids like nitrogen, argon, etc. as well as oxygen.

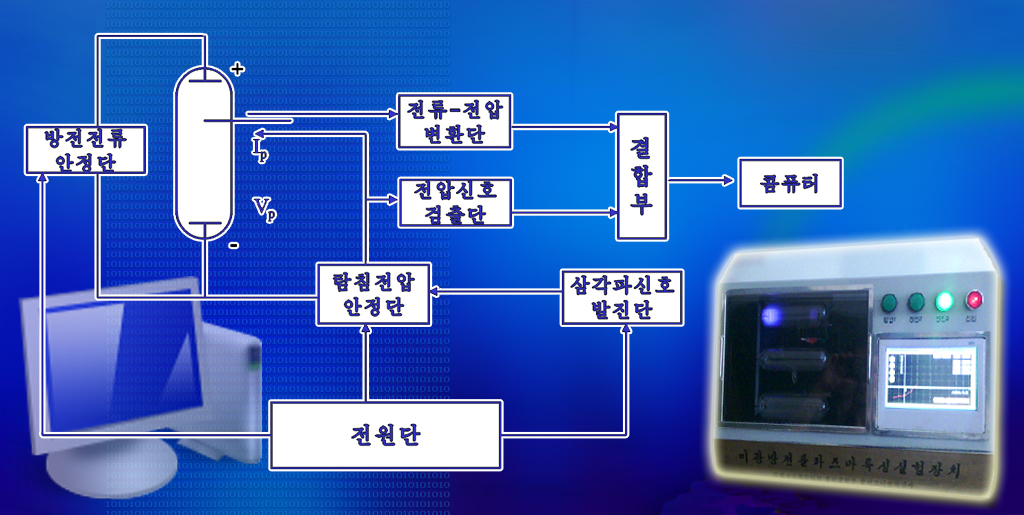

Computerized Experiment Device for Characteristics of Glow Discharge Plasma

Choe Yong Son, a researcher at the Faculty of Physics, realized the computerization of an experiment device to measure the characteristics of glow discharge plasma. Compared to the previous devices with analog meters, the computerized device is equipped with an embedded system and a touch-panel interface, which makes it possible to supervise and analyze experimental processes, and to display the results. It also ensures high accuracy in measurement and short time of measurement along with intuitiveness and effectiveness of experiments. The device consists of a power supply, a probe voltage stabilizer, a triangular signal generator, a discharge current sustainer, a current-to-voltage converter, a voltage signal detector, a matching unit, and a computer. The main characteristics to measure are electron density and electron temperature. A linearly increasing voltage is applied to the electrostatic probe, which is placed in the discharge region, and the current to the probe is captured at a regular interval, in order to gain voltage-current measurement points of the probe. These measured data are treated by 3-order spline interpolation and then by weighed polynomial method to obtain a voltage-current curve of the probe. Necessary features are to be derived from the characteristic curve, and these features are utilized to determine electron temperature and electron density. All these operations are automatically performed through its embedded system and touch-panel interface.

Choe Yong Son, a researcher at the Faculty of Physics, realized the computerization of an experiment device to measure the characteristics of glow discharge plasma. Compared to the previous devices with analog meters, the computerized device is equipped with an embedded system and a touch-panel interface, which makes it possible to supervise and analyze experimental processes, and to display the results. It also ensures high accuracy in measurement and short time of measurement along with intuitiveness and effectiveness of experiments. The device consists of a power supply, a probe voltage stabilizer, a triangular signal generator, a discharge current sustainer, a current-to-voltage converter, a voltage signal detector, a matching unit, and a computer. The main characteristics to measure are electron density and electron temperature. A linearly increasing voltage is applied to the electrostatic probe, which is placed in the discharge region, and the current to the probe is captured at a regular interval, in order to gain voltage-current measurement points of the probe. These measured data are treated by 3-order spline interpolation and then by weighed polynomial method to obtain a voltage-current curve of the probe. Necessary features are to be derived from the characteristic curve, and these features are utilized to determine electron temperature and electron density. All these operations are automatically performed through its embedded system and touch-panel interface.

This device can increase the measurement accuracy of probe voltage and current by more than 20 times and, as a result, as many measurement points as possible are available. Therefore, we can eliminate scale errors, which were indispensable in the past, and decrease random errors down to below 0.5% (in analog meter: 4.2%). In addition, offline experiments may become possible by the combination of serial communication and network communication.

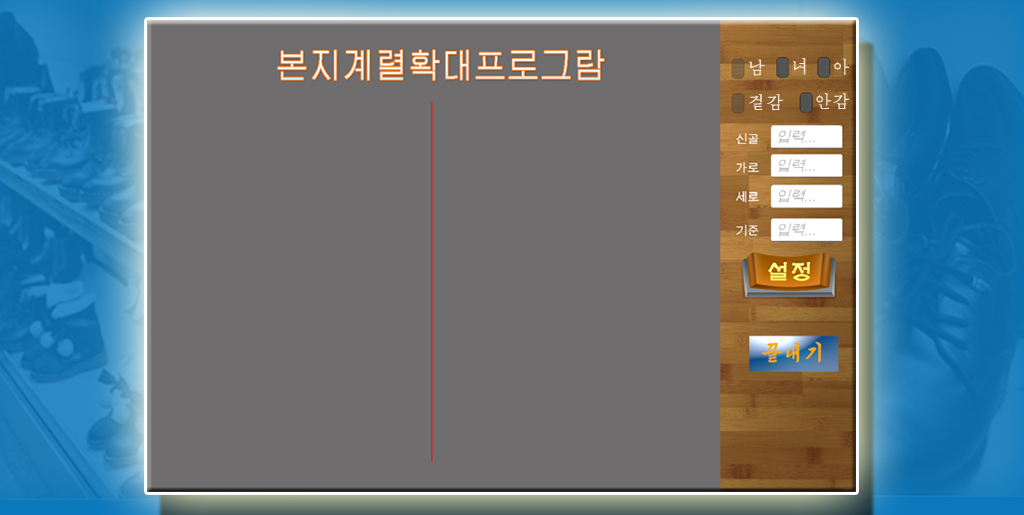

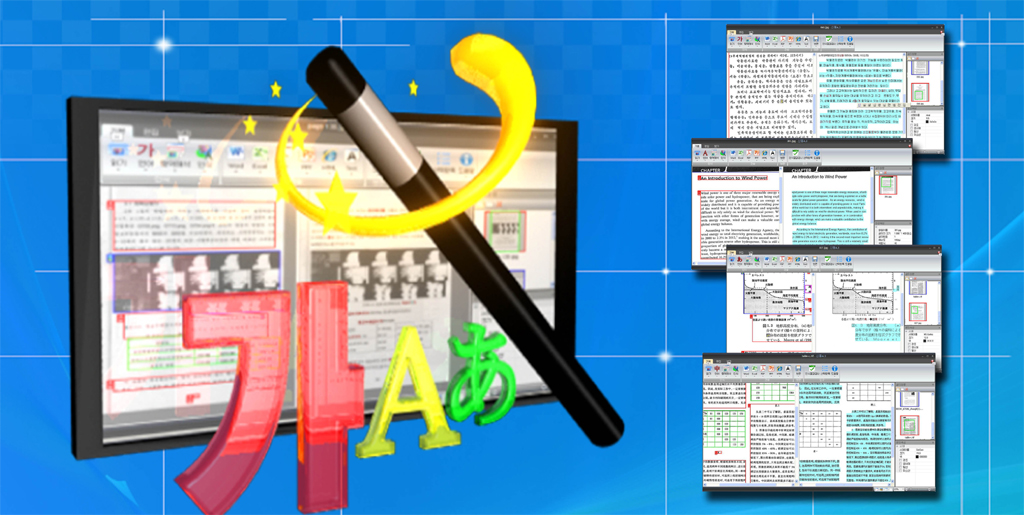

Shoe Design Serial Expansion Program Developed

Choe Song Bom, a section head at the Faculty of Information Science and Technology, has developed an image processor to obtain input images from hand-based shoe design images, and on the basis of it, he has continued to invent a new method of serial expansion and realize it in a serial expansion program.

Choe Song Bom, a section head at the Faculty of Information Science and Technology, has developed an image processor to obtain input images from hand-based shoe design images, and on the basis of it, he has continued to invent a new method of serial expansion and realize it in a serial expansion program.

This program consists of 3 parts: noise reduction, contour highlight, and serial expansion. Its application reduced design hours from 10 to 3 and improved design accuracy from 90% to 98%.

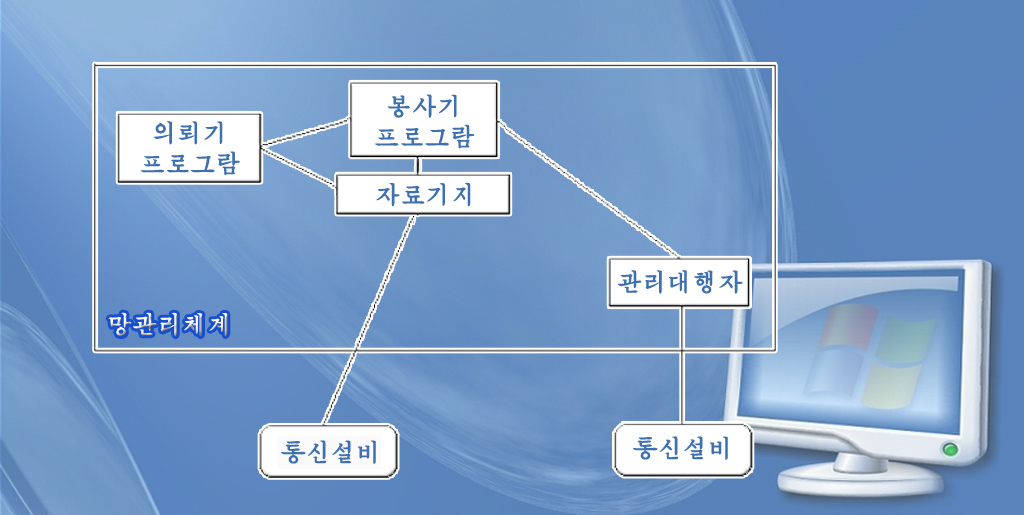

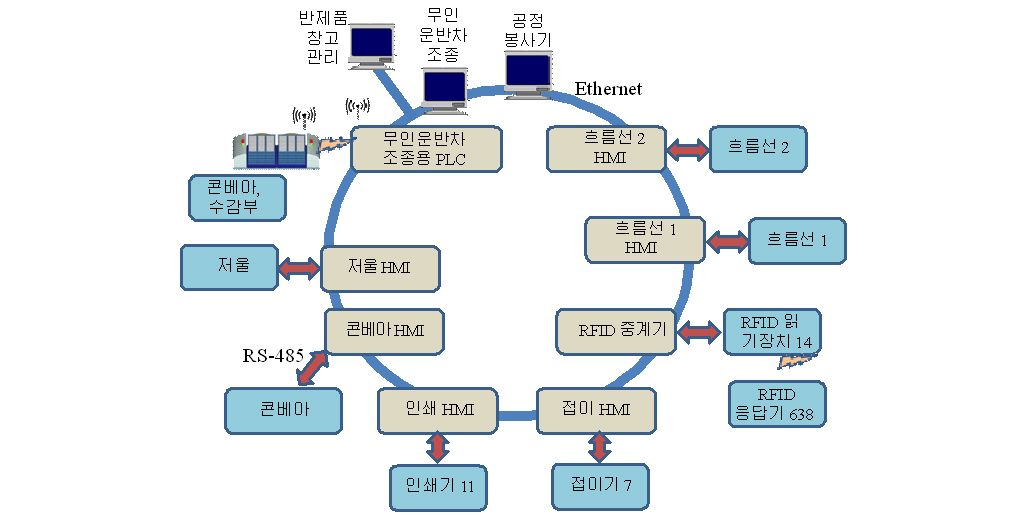

Network Management System Using Simple Network Management Protocol

In keeping with the actual conditions where communication equipment is on the increase in its kind and scale, the research team led by An Chong Il, a researcher at the Faculty of Information Science and Technology, has developed a network management system using a simple network management protocol that enables the integrated management of individual pieces of communication equipment. Thanks to it, it became possible to manage different pieces of existing communication equipment in an integrated way and also to satisfactorily supervise and manage newly-added ones.

In keeping with the actual conditions where communication equipment is on the increase in its kind and scale, the research team led by An Chong Il, a researcher at the Faculty of Information Science and Technology, has developed a network management system using a simple network management protocol that enables the integrated management of individual pieces of communication equipment. Thanks to it, it became possible to manage different pieces of existing communication equipment in an integrated way and also to satisfactorily supervise and manage newly-added ones.

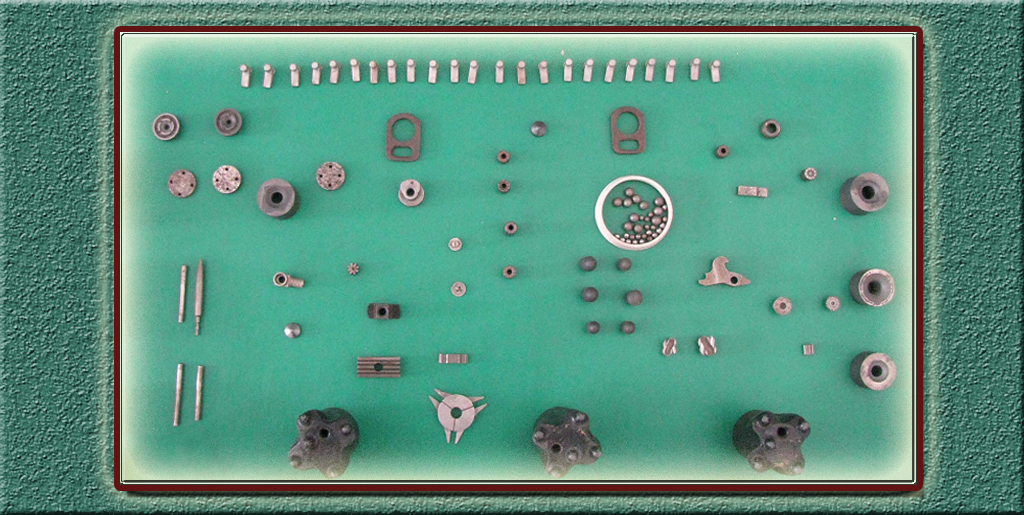

Debinding Method in MIM Products

The research group led by Sim Jae Rim, a section head at the Faculty of Materials Science and Technology has succeeded in the research into an effective method of debinding in metal injection molding (MIM) products.

The research group led by Sim Jae Rim, a section head at the Faculty of Materials Science and Technology has succeeded in the research into an effective method of debinding in metal injection molding (MIM) products.

They put MIM products made with paraffin-based binder in a benzol-acetone solution to remove soluble binder before heating them to remove insoluble binder, thus increasing debinding rate by more than 5% and reducing the duration of debinding by more than 2 hours.

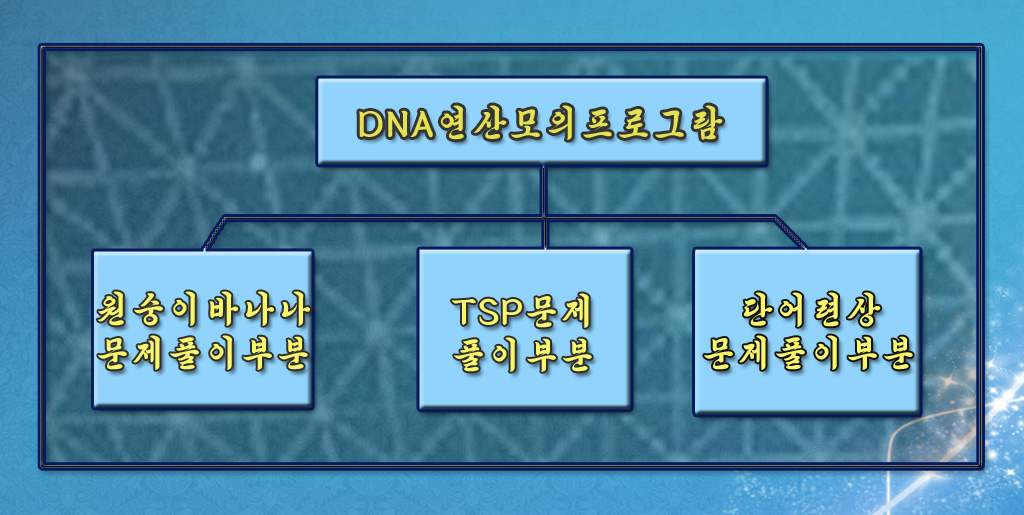

DNA Computing Simulation Program Developed

The research team led by Kim Sung Nam, an institute head at the Faculty of Information Science and Technology, has developed a DNA computing simulation program to perform parallel computations on a personal computer by applying a DNA encoding process, a branch of biochemistry, to the optimum solution of intellectual problems.

The research team led by Kim Sung Nam, an institute head at the Faculty of Information Science and Technology, has developed a DNA computing simulation program to perform parallel computations on a personal computer by applying a DNA encoding process, a branch of biochemistry, to the optimum solution of intellectual problems.

The program consists of 3 parts: monkey-banana problems, TSP problems and word association problems. This program is able to generate all possible paths and examine the possibility of optimization at the same time in parallel by simulating the DNA computing programmatically, in contrast to traditional optimal path-finding methods that generate all possible paths and then find one among them by examining conditions one by one. The average time of solving problems is about 20s (Core i3) and the accuracy reaches 95%.

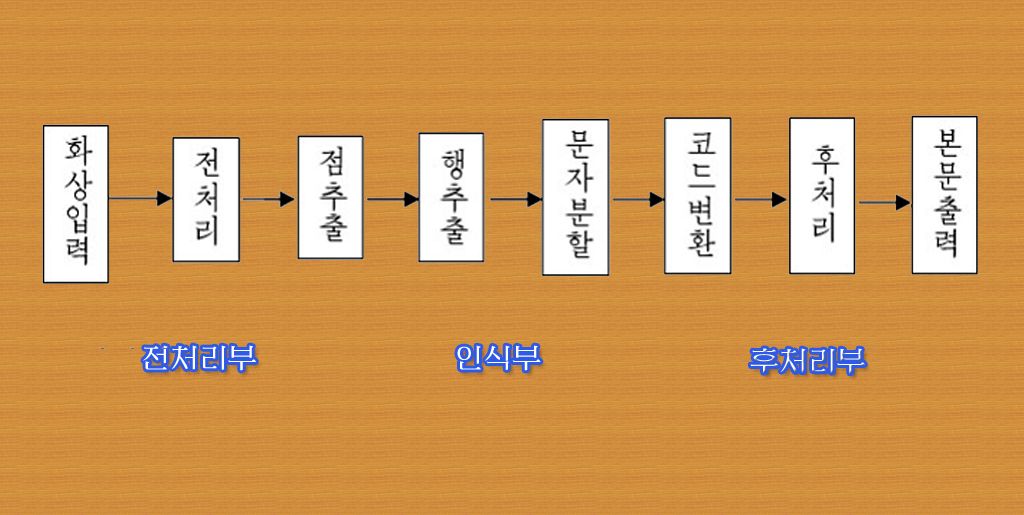

Korean Braille Character Reader of Our Style

The research group led by Ma Min Gon, vice dean of the Faculty of Information Science and Technology, has developed a Korean braille character reader which converts raised letters read by an image input device into a character code readable by ordinary people.

The research group led by Ma Min Gon, vice dean of the Faculty of Information Science and Technology, has developed a Korean braille character reader which converts raised letters read by an image input device into a character code readable by ordinary people.

When books published in raised type for the blind to read by groping are read by an image input device like a scanner, the raised parts are shown in dim dots. In order to extract these dim dots more precisely, they proposed and realized several new basic methods: binarization by wavelet difference image, tilt estimation by Hough conversion, dot extraction by dot database and Maharanobis distance for precise extraction without being affected by the scanning direction, charline extraction from dots capable of strongly overcoming noises, substitution of braille code for unicode by bidirection scanning, postprocess based on geometrical position of dots, etc.

Thus, they were able to raise the extraction precision up to 96% and the recognition speed up to 1 second per page.

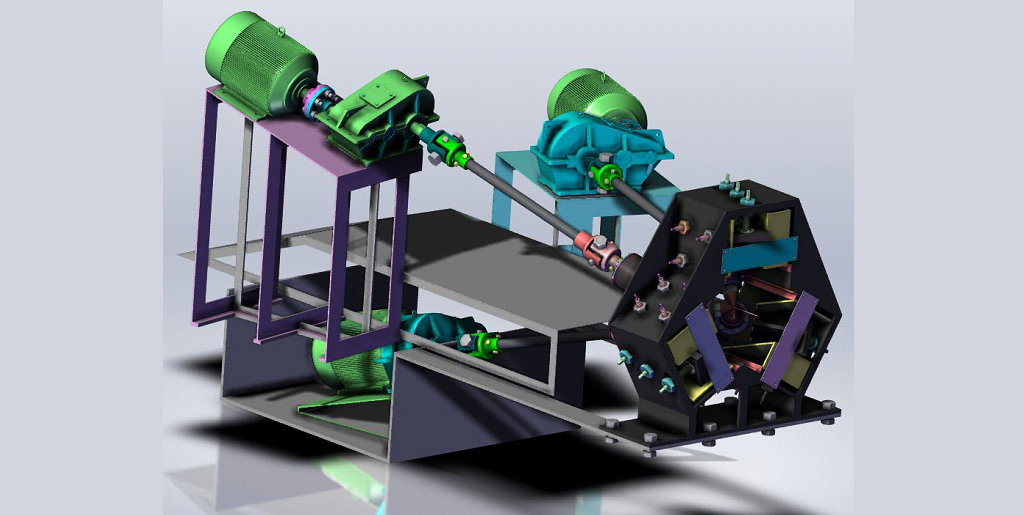

A Screw Rolling Process with Individually Driven Rollers Established

A research group led by Ri Yong Min, a researcher at the Faculty of Materials Science and Technology, has developed a screw rolling mill with individually driven rollers and established a rolling process which can produce bars of more than 20mm in diameter through one pass without a roller change from round steel of 50mm in diameter, consuming less power. They will no longer need an ordinary light section rolling mill in machine factories and repair bases that have a great demand for bars in various diameters. In this rolling process, round steel of 50mm in diameter is heated to 850~950℃ in a heating furnace and is rolled into bars of 20mm in diameter through one pass in a cantilevered 3-helical rolling mill with individually driven rollers that has a large feed angle and an elongation angle before they are cut into necessary lengths.

A research group led by Ri Yong Min, a researcher at the Faculty of Materials Science and Technology, has developed a screw rolling mill with individually driven rollers and established a rolling process which can produce bars of more than 20mm in diameter through one pass without a roller change from round steel of 50mm in diameter, consuming less power. They will no longer need an ordinary light section rolling mill in machine factories and repair bases that have a great demand for bars in various diameters. In this rolling process, round steel of 50mm in diameter is heated to 850~950℃ in a heating furnace and is rolled into bars of 20mm in diameter through one pass in a cantilevered 3-helical rolling mill with individually driven rollers that has a large feed angle and an elongation angle before they are cut into necessary lengths.

Thus, they can produce bars of different diameters from short scrap iron by changing no rolls but adjusting the roll gap, and ensure the metal yield of more than 99% and the roundness of ±0.1.

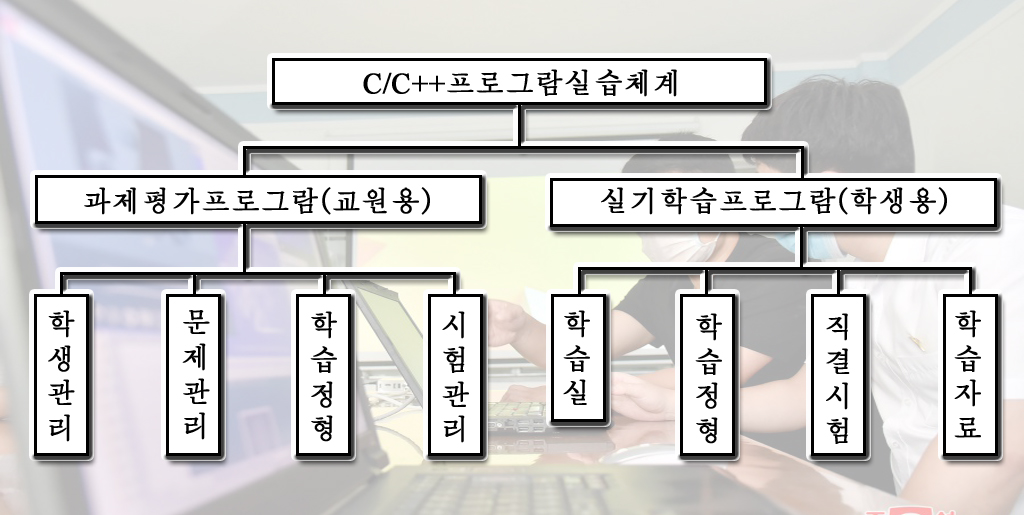

C/C++ Programming Evaluation System Developed

Kim Won Ok, a researcher at the Faculty of Information Science and Technology, has developed a C/C++ programming evaluation system to raise practical programming skills of students who are learning C/C++ programming including those who are receiving distance education, and to make an accurate evaluation of the programming assignments performed by them.

Kim Won Ok, a researcher at the Faculty of Information Science and Technology, has developed a C/C++ programming evaluation system to raise practical programming skills of students who are learning C/C++ programming including those who are receiving distance education, and to make an accurate evaluation of the programming assignments performed by them.

What she has done includes the combination of web and other applications by TCP socket communication, the implementation of a C/C++ programming environment by C++ compiler and I/O stream pipeline, accurate evaluation of assignment performance, and the security of learning-related data including assignments by user certification, copy paste protection and encryption.

She herself tried making and running a program so as to make a programming tool and a system for evaluating programming accuracy. This helped raise students’ programming skills and enthusiasm for study, and evaluate their assignment performance rapidly and accurately.

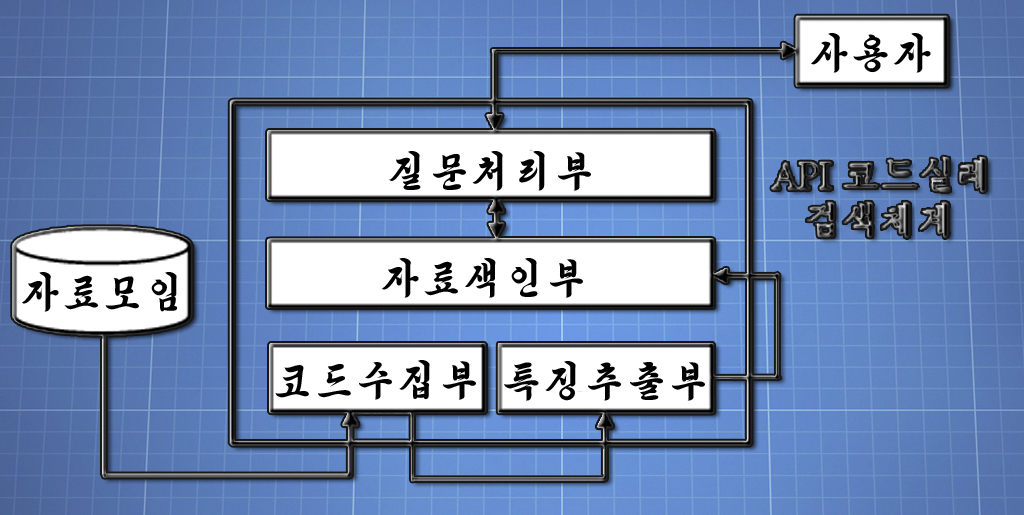

Newly-Developed Java API Compound Retrieval Program

Pak Il Chol, a researcher at Faculty of Information Science and Technology, has developed a Java API compound retrieval program on the basis of the collection of code snippets and feature extraction. In this program it is possible to realize ranking of code snippets suitable for user intention from their application degree and brevity degree. He increased the rate of indexing by 0.3GB per hour and the precision and recall by 6% and 9% respectively, which resulted in the improvement of the development speed and quality of programs. Thus, he ensured the guarantee for reducing the labour and time needed for program development to one tenth.

Pak Il Chol, a researcher at Faculty of Information Science and Technology, has developed a Java API compound retrieval program on the basis of the collection of code snippets and feature extraction. In this program it is possible to realize ranking of code snippets suitable for user intention from their application degree and brevity degree. He increased the rate of indexing by 0.3GB per hour and the precision and recall by 6% and 9% respectively, which resulted in the improvement of the development speed and quality of programs. Thus, he ensured the guarantee for reducing the labour and time needed for program development to one tenth.

Optical Passingtime Detector

Kong Myong Il, a researcher at Semi-conductor Institute, and his research group have developed PTC (positive temperature coefficient) resistance material necessary for constant operation of facilities under the condition of room temperature even in low-temperature zones, and they have been expanding their achievements. This material provides room temperature resistance of 20Ω, Curie temperature of 30℃ and temperature coefficient of resistance of over 18%/℃.

Kong Myong Il, a researcher at Semi-conductor Institute, and his research group have developed PTC (positive temperature coefficient) resistance material necessary for constant operation of facilities under the condition of room temperature even in low-temperature zones, and they have been expanding their achievements. This material provides room temperature resistance of 20Ω, Curie temperature of 30℃ and temperature coefficient of resistance of over 18%/℃.

Optical Passingtime Detector

Kang Hwi Song, a researcher at Faculty of Electronic Engineering, and his research group have succeeded in manufacturing an Optical Passingtime Detector using infrared optical technology and Zigbee wireless communication and are expanding their achievements. This detector ensures speed measurement accuracy of 0.01s in a 30-meter section which is an important item in selecting and training reserve footballers.

Kang Hwi Song, a researcher at Faculty of Electronic Engineering, and his research group have succeeded in manufacturing an Optical Passingtime Detector using infrared optical technology and Zigbee wireless communication and are expanding their achievements. This detector ensures speed measurement accuracy of 0.01s in a 30-meter section which is an important item in selecting and training reserve footballers.

As it is portable, it can be taken for camping drill and also be used in outdoor conditions with high illuminance as well as indoors. Moreover, it offers high stability and accuracy of speed measurement. The range of time measurement is 0~100s and the measurement accuracy is 0.01s.

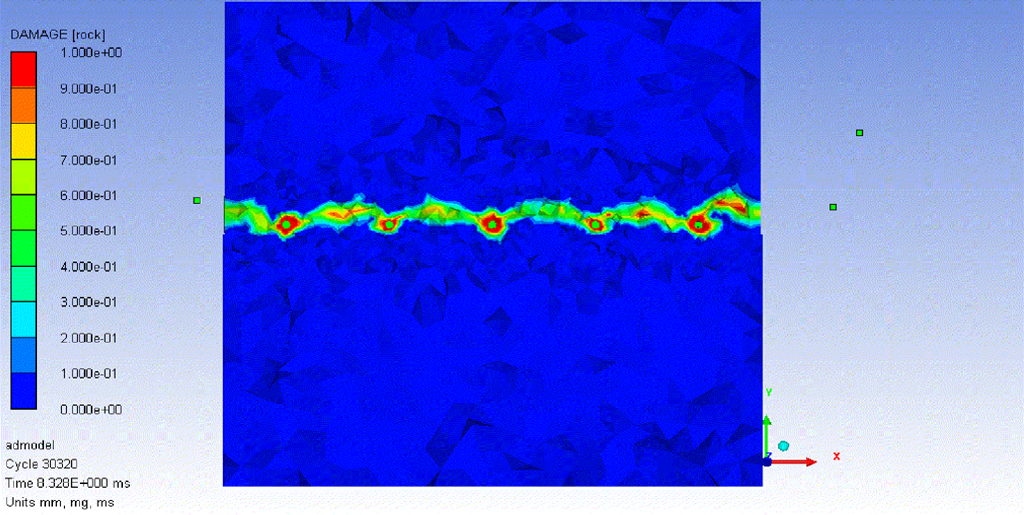

Ways to Improve Simultaneous Initiation Property

Pak Thae Un, a section head at Faculty of Mining Engineering, studied and introduced a simultaneous blasting method by a high-voltage blaster whereby they could improve rock cutting property by enhancing the effects of simultaneous blasting in blasting operations.